When we engrave on a PVC foam board, how can we ensure its engraving surface is smooth?

- Share

- Issue Time

- Dec 3,2018

When we engrave on a PVC foam board, how can we ensure its engraving surface is smooth?

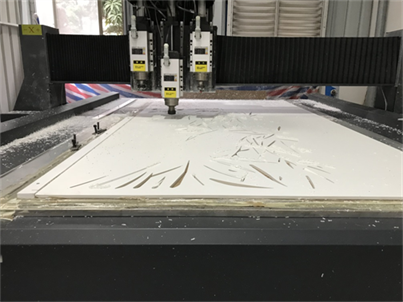

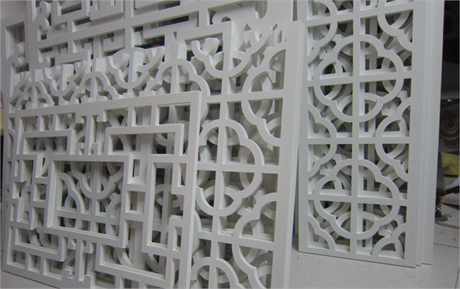

PVC foam board, an ideal material that is widely used in advertising, furniture cabinets and interior decoration etc. PVC foam boards are often used to engrave into a variety of designed shapes. So how can an engraving surface be smooth without burrs, showing a beautiful appearance? There are some tips for your reference.

Material

Choose a PVC foam board suitable for engraving. From the technical point of view, PVC celuka foam board should be given priority, followed by PVC co-extruded foam board and PVC free foam board; In terms of density, try to choose the foam board with a density higher than 0.5g/cm3; In terms of the appearance, select a foam board without bubbles in the cross section.

The quality of PVC foam board is a key factor that contributes to the smoothness in the engraving.

Engraving Tool

First, the appropriate engraving tool should be selected according to the design pattern. There are many types of engraving tools, of which the diameter, length, and shapes are different. Single blade, double blade, flat bottom, pointed bottom and round bottom; diameter ranging from 3.175mm, 4mm, 5mm, 6mm, 8mm, 10mm etc. And then comes to cylindrical shape, V-shaped and slotted shaped etc.

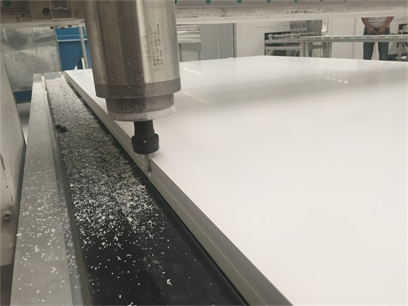

Secondly, the long-term use of the engraving tool will cause itself to wear seriously and become blunt, resulting in a non-smooth cutting surface. Therefore, it is necessary to change the tool regularly to ensure a smooth cutting surface. It is advised to choose the right tool and carefully observe it during the engraving process. If the cutting surface is not smooth, please replace the tool in time.

Both the path setting of the engraving tool and its rotating directionhave a great influence on the smoothness of the cutting surface. You can improve the smoothness of the cutting surface by changing the tool’s direction in the software.

For example, when producing embossing effect on the board and trimming straight edges along it, we can use the pointed knife to make surface engraving. Then, change to straight knife for trimming. So you can see this is a process that is completed by two types of engraving tools.

If the customer does not require the edge of the product to be straight, then it is usually carved and cut with only a pointed knife, saving the trouble of changing knifes during the process. However, the finished cutting will be a bit angled. Some customers with low requirements think it acceptable, and the processing price is relatively cheaper. If the customer wants the cutting edge to be straight, it must be cut with a straight knife and the processing cost will increase.

The straight knife is trimming.

Rotating speed and running speed of the engraving tool

The engraving tool that rotates and runseither too fast or too slowly will result in rough engraving. Therefore, we should adjust the rotating and running speed to find a balance between engraving effect and economic benefit. Apart from that, we need to sum up experience during the process to find the most suitable rotating and running speed.