What is a High Density PVC Foam Board?

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Apr 17,2024

Summary

Discover the benefits of high density PVC foam board from a leading PVC foam board manufacturer. Our superior strength and durable foam board solutions offer high performance and customization options to meet your project needs.

PVC foam board has established itself as a versatile and reliable material in numerous industries, thanks to its lightweight yet durable nature. Composed of polyvinyl chloride (PVC) and foaming agents, PVC foam board offers a unique combination of strength, rigidity, and versatility that makes it suitable for a wide range of applications. From signage and displays to construction and manufacturing, PVC foam board has become a go-to choice for projects requiring ease of fabrication and long-lasting performance.

However, for applications demanding enhanced strength and durability, high density PVC foam board emerges as a superior alternative. Engineered with a denser cellular structure, high density PVC foam board offers greater mechanical properties, making it ideal for projects where standard PVC foam board may fall short. In this article, we will explore the characteristics, applications, benefits, and customization options of high density PVC foam board, providing insight into its value and versatility in today's market.

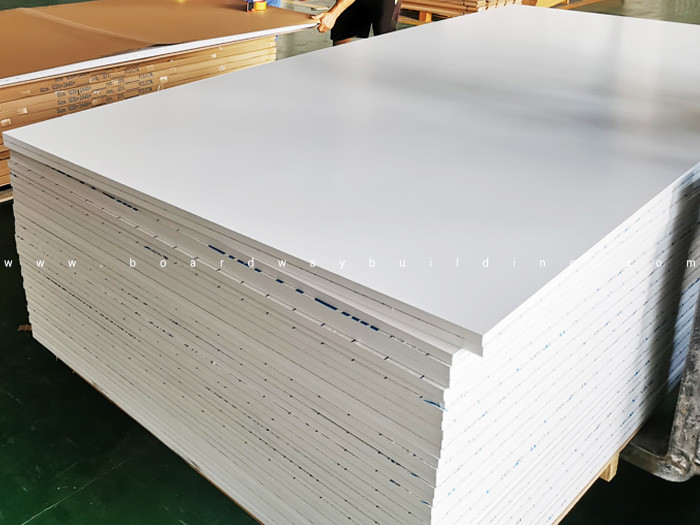

PVC Foam Board

Production of PVC Board

Characteristics of High Density PVC Foam Board

Definition of high density PVC foam board

High density PVC foam board, refers to a specialized variant of PVC foam board with a denser cellular structure. While the term "foam" typically suggests a lightweight and porous material, high density PVC foam board is actually characterized by its lower foaming degree, resulting in a more solid and compact structure. This denser composition provides high density PVC foam board with superior strength, rigidity, and durability compared to standard PVC foam board.

Differentiation from standard PVC foam board

Standard PVC foam board is produced with a higher degree of foaming, resulting in a lighter and less dense material with more air pockets within its cellular structure. In contrast, high density PVC foam board is manufactured with a lower degree of foaming, allowing for fewer air pockets and a denser cellular structure. This difference in foaming degree leads to contrasting characteristics, with standard PVC foam board being lighter and less rigid, while high density PVC foam board is heavier and more rigid.

Standard PVC Foam Board

High Density PVC Foam Board

Key characteristics of high density PVC foam board

1. Enhanced strength and rigidity: The denser cellular structure of high density PVC foam board provides increased structural integrity and load-bearing capacity compared to standard PVC foam board. This makes it suitable for applications requiring higher levels of strength and durability.

2. Improved impact resistance: The compact composition of high density PVC foam board enhances its ability to withstand impact and mechanical stress. This makes it an ideal choice for applications where the material may be subjected to rough handling or frequent impacts.

3. Smoother surface finish: High density PVC foam board typically features a smoother surface finish compared to standard PVC foam board. This results in improved printability, paintability, and surface aesthetics, making it suitable for applications where visual appearance is important.

4. Enhanced dimensional stability: High density PVC foam board exhibits superior dimensional stability compared to standard PVC foam board. Its denser cellular structure minimizes expansion and contraction in response to changes in temperature and humidity, ensuring that the material maintains its shape and dimensions over time.

3. Smoother surface finish: High density PVC foam board typically features a smoother surface finish compared to standard PVC foam board. This results in improved printability, paintability, and surface aesthetics, making it suitable for applications where visual appearance is important.

4. Enhanced dimensional stability: High density PVC foam board exhibits superior dimensional stability compared to standard PVC foam board. Its denser cellular structure minimizes expansion and contraction in response to changes in temperature and humidity, ensuring that the material maintains its shape and dimensions over time.

In summary, high density PVC foam board offers a range of advantageous characteristics stemming from its denser cellular structure, including enhanced strength, rigidity, impact resistance, surface finish, and dimensional stability. This makes it a preferred choice for applications requiring robust and reliable performance.

Applications of High Density PVC Foam Board

1. Signage and Displays

High density PVC foam board is widely utilized in the signage and display industry due to its exceptional strength, rigidity, and durability. Its ability to maintain dimensional stability and withstand external elements makes it an ideal choice for outdoor signage, including billboards, shop signs, and directional signs. Additionally, its smooth surface finish allows for vibrant and high-quality printing, making it suitable for indoor displays, exhibition stands, and promotional materials.

2. Construction and Architectural Elements

High density PVC foam board finds extensive use in the construction and architectural sectors for various applications. Its superior strength and structural integrity make it suitable for constructing architectural elements such as decorative trim, moldings, cornices, and columns. Additionally, high density PVC foam board is often used for cladding, facade systems, and partition walls due to its weather resistance, impact resistance, and ease of installation.

3. Industrial and Manufacturing Applications

In industrial and manufacturing settings, high density PVC foam board serves a multitude of purposes due to its robustness and versatility. It is commonly utilized for manufacturing components and parts in industries such as automotive, aerospace, and electronics. Its ability to be machined, routed, and fabricated into complex shapes makes it an ideal choice for producing prototypes, jigs, fixtures, and tooling.

4. Marine and Outdoor Applications

High density PVC foam board is highly sought after for marine and outdoor applications where resistance to water, moisture, and harsh environmental conditions is paramount. It is extensively used for boat building, marine decking, and cabinetry due to its excellent waterproof properties and resistance to saltwater corrosion. Additionally, high density PVC foam board is utilized in outdoor furniture, pergolas, and landscape structures, providing a durable and low-maintenance alternative to traditional materials like wood and metal.

In summary, high density PVC foam board offers a versatile solution for a wide range of applications across various industries. From signage and construction to industrial manufacturing and marine use, its exceptional strength, durability, and resistance properties make it a preferred choice for projects requiring reliability and performance in demanding environments.

Customization Options and Availability

1. Thickness Options and Sheet Sizes

High density PVC foam board is available in a variety of thickness options and sheet sizes to accommodate diverse project requirements. Common thicknesses range from 3mm to 30mm, with standard sheet sizes typically measuring 4ft x 8ft or 1220mm x 2440mm. However, custom thicknesses and sheet sizes can be readily produced to meet specific customer specifications and project needs. Whether you require thin sheets for intricate detailing or thick panels for structural applications, high density PVC foam board can be tailored to your exact requirements.

2. Color Choices and Surface Textures

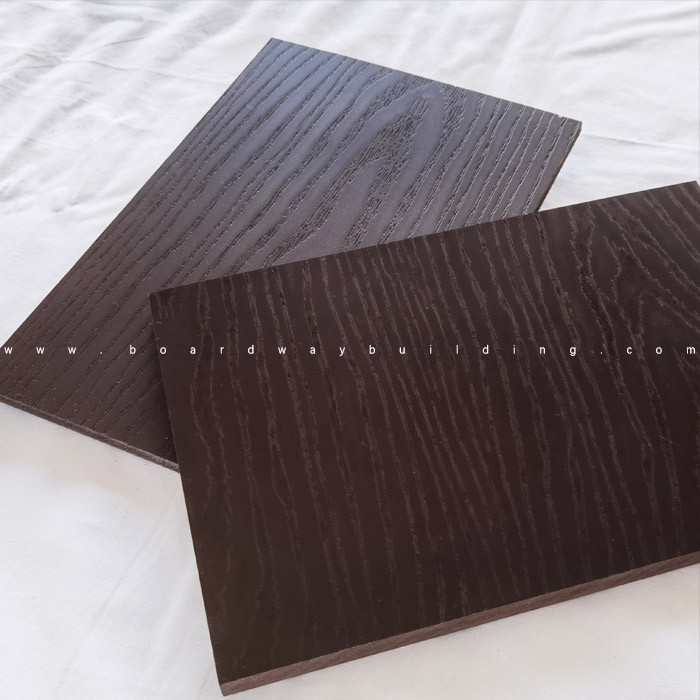

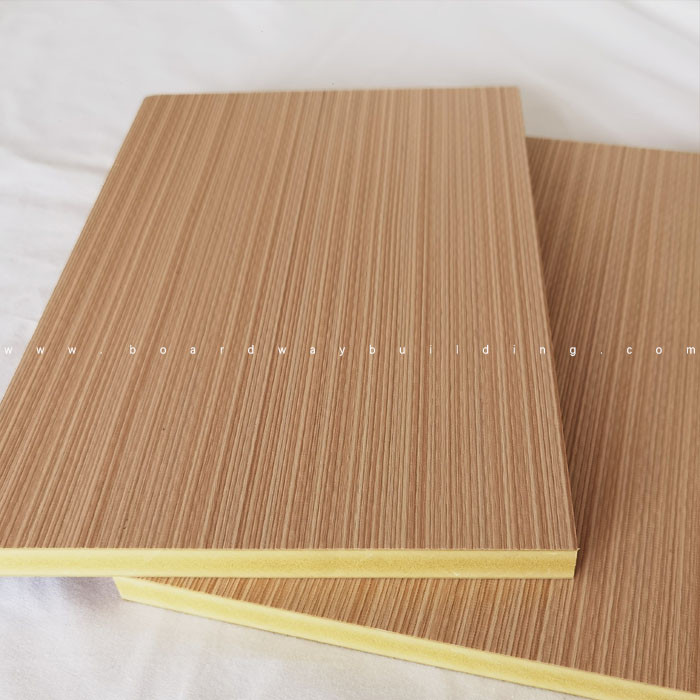

High density PVC foam board offers a wide range of color choices and surface textures to suit various aesthetic preferences and design considerations. Standard colors include white, black, and gray, with the option for custom colors available upon request. Additionally, high density PVC foam board can be produced with different surface textures, such as smooth, matte, or embossed finishes, to enhance visual appeal and functionality. Whether you prefer a sleek and modern appearance or a textured surface for improved grip and traction, high density PVC foam board provides customizable options to bring your vision to life.

Matte PVC Foam Board

Wood Grain PVC Foam Board

PVC Decorative Panel

3. Availability through Boardway as a Leading Manufacturer

As a leading manufacturer of PVC foam board in China, Boardway offers high quality and customizable high density PVC foam board solutions to customers worldwide. With state-of-the-art production facilities and stringent quality control measures, Boardway ensures that its high density PVC foam board meets the highest standards of performance, reliability, and consistency. Whether you require standard thicknesses and sizes or custom specifications, Boardway can fulfill your needs with prompt delivery and exceptional service. With Boardway as your trusted partner, you can count on premium quality high density PVC foam board that exceeds expectations for your projects.

Throughout this article, we have explored the numerous advantages and applications of high density PVC foam board that make it a top choice for a variety of projects. With its denser cellular structure, high density PVC foam board provides enhanced strength, rigidity, and durability compared to standard PVC foam board, making it suitable for demanding environments and applications where reliability is paramount.

As a leading manufacturer of PVC foam board in China, Boardway is committed to delivering high quality and customizable high density PVC foam board solutions to customers worldwide. With our expertise, innovation, and dedication to customer satisfaction, we stand ready to meet your project needs and exceed your expectations. Consider high density PVC foam board from Boardway for your next project and experience the difference in performance and quality.