Can corrugated plastic sheet, plastic honeycomb panel and X type hollow sheet be used outdoors?

- Share

- Issue Time

- Nov 20,2018

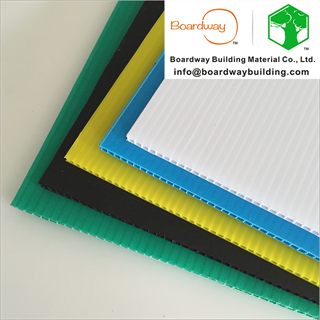

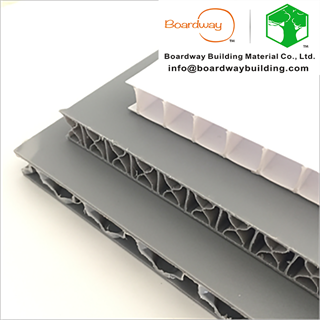

Can corrugated plastic sheet, plastic honeycomb panel and X type twin wall hollow sheet be used outdoors?

If the above 3 kinds of PP corrugated sheets are to be used for a long time under the conditions of sun and rain, they need to be able to resist aging. So, how can we slow down the aging speed of these PP corrugated sheets?

First of all, we need to know the outdoor conditions where the PP corrugated sheets are used:

1. Intensity of sun exposure (annual average ultraviolet radiation, continuous data of at least 10 years)

2. Humidity and annual precipitation

3. The lowest temperature

PP Honeycomb Sheet & X Type Twin Wall Hollow Sheet

Besides, we also need to know how long the PP corrugated sheets can be used.

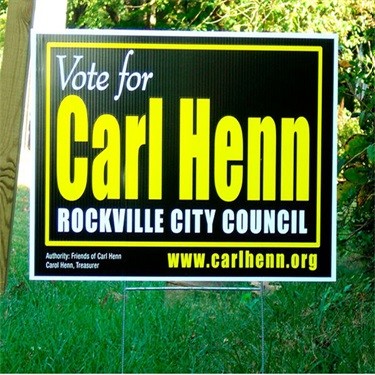

Generally speaking, PP corrugated sheets for outdoor use are applied to advertising, carriages and construction sites etc. The life span depends on using environment and these sheets' application.

The higher the ultraviolet light, the more precipitation, the more humid the environment, and the lower the temperature, the aging speed of the PP plastic hollow board will be faster.

PP corrugated sheets are deteriorated by light, heat, moisture, oxidation and other factors, which cause the material to fade and lose its original mechanical properties.

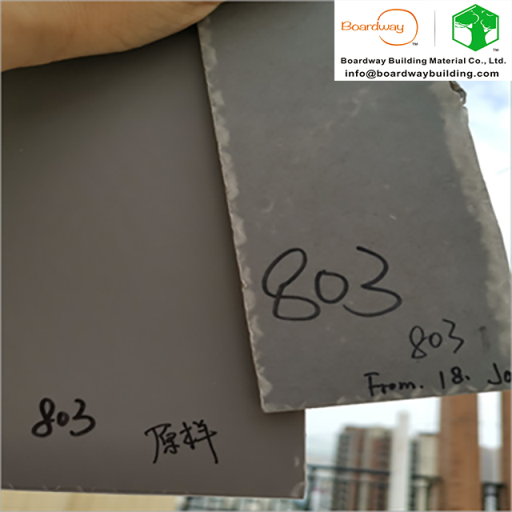

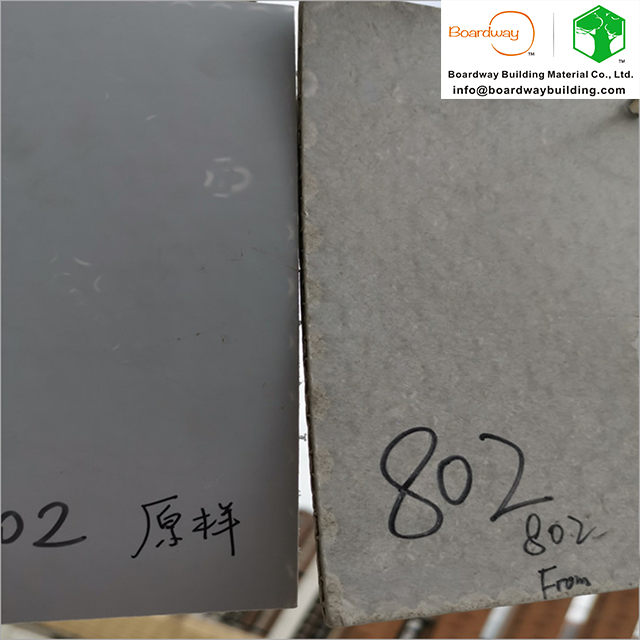

After adding anti-UV agent to the sample, the change is not obvious after 12 months of sun and rain.(from Jan 2018 to Oct 2018)

However, the sample without the anti-UV agent has a poorer effect for outdoor use under the same weather condition for 12 months

Therefore, to slow down the aging rate of PP corrugated sheets, the production formula can be appropriately adjusted according to different uses as follows:

1.Adding appropriate ultraviolet light absorber and antioxidant can effectively improve the sheets' weathering resistance.

2.To maintain the durability of the color, it is necessary to add weathering pigment to adjust the color of the swatch, such as iron oxide red, phthalocyanine blue, carbon black, green, and dioxin color, which can improve its weather resistance.

3.In the polypropylene hollow sheet formula, adding an appropriate amount of dioxins can greatly improve the weathering resistance.

4. In the polypropylene hollow sheet formula, a certain antimony stabilizer is added to replace the lead salt stabilizer, which has a corresponding improvement on the impact toughness and atmospheric aging resistance.

For Boardway (Polyreflex's) plastic sheets, life spans of different products are as below:

1. PP corrugated sheets can be used outdoors for 2 years.

UV Absorber

Standard products can be used outdoors for 3 years; if there are special requirements like extending the life span of the product, high-quality UV absorber can be added to meet more than 5 years service life.