What Are the Differences Between the 3 Types of PVC Foam Boards?

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Apr 24,2022

Summary

There are 3 types of PVC foam board: pvc celuka board, pvc free foam board and pvc co-extruded board. They differ in appearance, size and performance. We can choose them according to the purpose.

What Are the Types of PVC Foam Board?

It is certain that most people who know rigid PVC foam board (expanded PVC sheet) know that there are three types of PVC foam board, which are pvc free foam board, pvc celuka foam board and pvc co-extruded foam board. However, do we know what are the differences between these three? And, which type of PVC foam board should be used for our purposes?

To answer these questions, we analyze the differences between these three types of PVC foam boards from manufacturing technique, appearance, performance, specification, price. And, some common uses for each of them.

Click to view videos about PVC foam board at https://www.boardwaybuilding.com/comm03/Video.htm

What Are the Differences Between Them?

MANUFACTURING TECHNIQUE

The naming of these three types of PVC foam boards is derived from their manufacturing technique. In the previous blog, we shared the manufacturing process of PVC foam board. We can know that PVC foam board is made of PVC resin mixed with other auxiliary materials, foamed, and then extruded through the mouth die and shaped into a board. So, what are the specific differences between the manufacturing processes of pvc free foam board, pvc celuka board and pvc co-extruded board?

After the PVC raw material melt leaves the mouth die, it continues to expand freely to a certain distance under the action of the foaming agent, and is shaped into a board by shaping dies. The PVC foam board produced by the free foaming process has a thinner skin, and the density of the inner core and outer layers is about the same.

The opposite of the free foaming process is controlled foaming process. Controlled foaming means that the PVC raw material melt is rapidly cooled as soon as it leaves the mouth die, preventing the surface of the PVC foam board from continuing to foam. The cooling methods include water cooling and oil cooling. The celuka process belongs to controlled foaming process. The PVC celuka board has a harder skin, and the density of the outer layer is greater than that of the inner core.

The co-extrusion process also belongs to controlled foaming process. The production equipment of PVC co-extruded board is different from that of PVC free foam board and PVC celuka board. The production equipment of PVC co-extruded board has more than one raw material barrel, but two. One of the barrels provides the raw material for the inner core and the other provides the raw material for the two surfaces. The PVC raw material melt enters the mold from two raw material barrels at the same time and extrudes to form the surface layer, inner core and bottom layer of the board respectively. The PVC foam board produced by the co-extrusion process has a relatively obvious three-layer structure. The top and bottom layers are not foamed, so the PVC co-extruded board has a harder outer layer.

Production of PVC Free Foam Board

Production of PVC Celuka Board

Production of PVC Co-extruded Board

APPEARANCE

It can be said that different manufacturing processes determine the appearance of PVC free foam board, PVC celuka board and PVC co-extruded board.

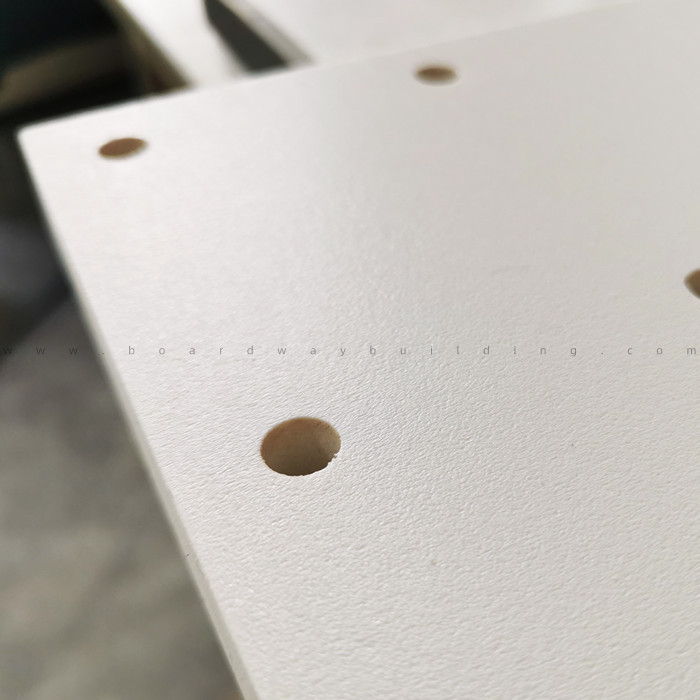

- The surface of the PVC free foam board is formed by the contact between the cells and the shaping die. Due to the free foaming process, the surface retains a fine uneven surface. It can be seen from the sides that the cell pores distributed in the surface layer and the middle core are uniform in size.

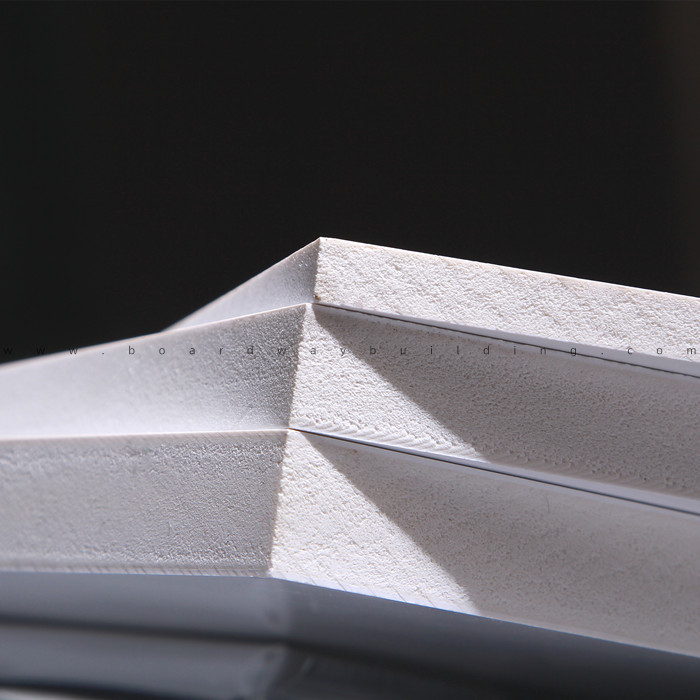

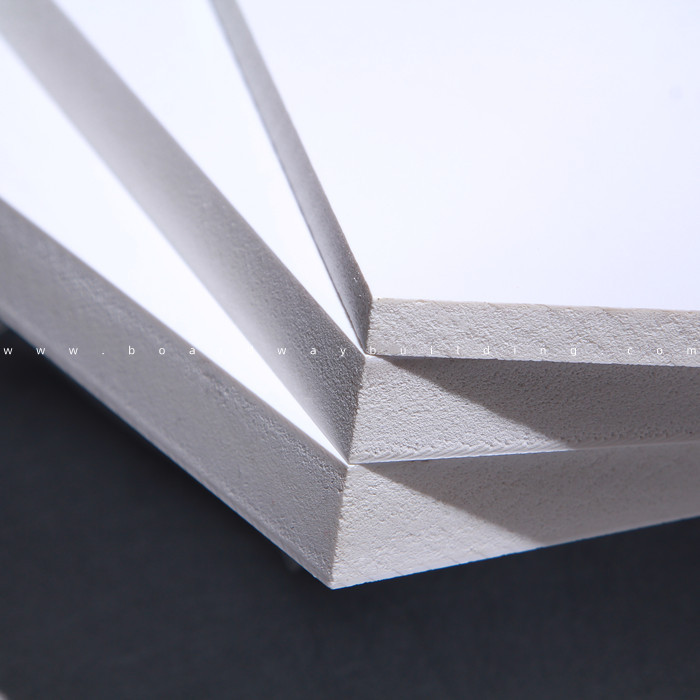

- The manufacturing process of PVC celuka board has one more cooling process than PVC free foam board. After being rapidly cooled, a rigid skin is formed on both surfaces of the board. The surface of PVC celuka board is flat and smooth without impurities, pits or bumps. Looking at its sides, we can see that the change of cells is gradually and uniformly smaller from the middle core to the surface layer and the bottom layer.

- The appearance of PVC co-extruded board is relatively easy to identify. It has the same smooth surface as PVC celuka board, even a glossy surface. Therefore, sometimes we may not be able to tell whether it is PVC celuka board or PVC co-extruded board just from the surface. But looking at the side of the PVC co-extruded board, we can find that its two surface layers and the middle core have obvious delamination. The two surface layers are not foamed and therefore solid. And the cell pores in the middle core are all of the same size and uniformity.

Remarks: For too thin PVC foam sheet, we may not easily observe the change of cell pores on the side. PVC foam sheets with a thickness of more than 10mm will be easier to identify. Friends who are interested in this can contact us to get a free sample and ship through the freight collect account.

There is no difference in chemical properties between pvc free foam board, pvc celuka board and pvc co-extruded board. They are all waterproof, mildewproof, and self-extinguishing when away from fire.

What differentiates them is the physical properties. In terms of strength, both pvc celuka board and pvc co-extruded board have better performance than pvc free foam board. Because the harder two surfaces allow them to obtain a better rigid structure. However, it does not mean that the physical properties of pvc free foam board are not good. When we are looking for a more flexible and bendable plastic material, pvc free foam board with a low density is the best choice.

|

PVC Free Foam Board

|

PVC Celuka Board

|

PVC Co-extruded Board

|

|

|

Standard Width

|

1220mm, 1560mm, 2050mm

|

1220mm, 915mm

|

1220mm

|

|

Length

|

The length of the extruded plastic sheet is not limited. Common lengths are 1830mm, 2440mm, 3050mm

|

||

|

Thickness

|

1mm - 25mm

|

3mm - 30mm

|

3mm - 20mm

|

Density | 0.45 - 0.9 g/cm3 | 0.4 - 1.1 g/cm3 | 0.4 - 0.9 g/cm3 |

The main reason for their price difference lies in the material consumption and energy consumption in the manufacturing process, that is, the production cost.

As far as our own factory is concerned, the price comparison of the three types of PVC foam boards is:

PVC co-extruded board ﹥ PVC free foam board ﹥ PVC celuka board

PVC Free Foam Board

PVC free foam board is also called PVC sign board because of its wide use in the advertising industry. It has a fine matt surface, which has good adhesion to ink and adhesive, so it is conducive to printing, spray coating, and laminating. When used as a billboard or sign, it can be used both indoors and outdoors. In addition, as a rigid foam board, PVC free foam board has the advantages of light weight, large size and low price compared with solid plastic boards of the same size.

PVC Celuka Board

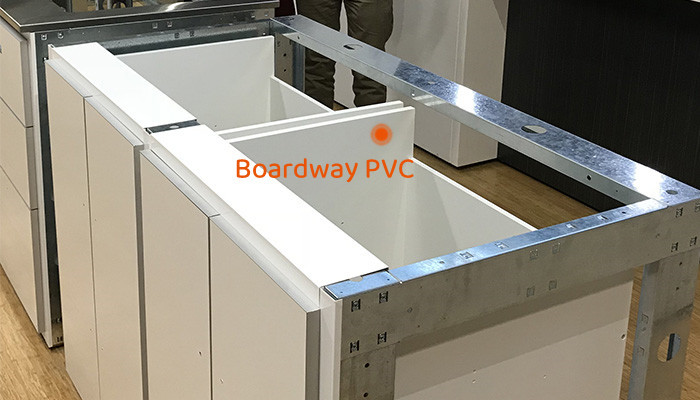

PVC celuka board has a very smooth surface, high hardness, and is not easy to be scratched. In addition, its waterproof, mildew-proof and termite-proof properties make it commonly used in making cabinets in kitchen and bathroom, furniture, etc. And PVC foam board is free of formaldehyde and can be self-extinguishing from fire (fireproof reinforcement board meets ASTM E84 grade A), these characteristics are not found in wooden board. That's why we call PVC celuka board PVC building board. If you want to use the PVC celuka board as the exterior panel of the cabinet, you can also choose the board laminated with the decorative surface, and the aesthetics will be greatly improved.

PVC Co-extruded Board

PVC co-extruded board can be said to be an upgraded version 2.0 of PVC celuka board. It has a closer performance to PVC celuka board, but we have strengthened the hardness of its two surfaces. The combination of the solid surface and the foamed inner core not only retains its advantages of light weight and good strength structure, but also increases the surface hardness, making the overall appearance of the board more glossy and beautiful. PVC co-extruded board can usually be used directly in decoration and furniture making. For example, one of our customers uses high density PVC co-extruded board to make cabinets on ambulances. Another customer makes movable self-assembling houses, and they use PVC co-extruded board for the house's wall panels and ceilings.

|

PVC Free Foam Board

|

PVC Celuka Board

|

PVC Co-extruded Board

|

|

|

Manufacturing Technique

|

Free foaming process

|

Celuka process

|

Co-extruded process

|

|

Appearance

|

Matt surface, uniform cell pores on the side

|

Smooth surface, the cell pores on the side gradually become smaller from the middle to the two surfaces

|

Glossy surface, with two solid surfaces and uniform cell holes on the side

|

|

Performance

|

Soft surface

|

Rigid surface and good strength structure

|

Ultra-hard surface and good strength structure

|

Price | Middle | Bottom | Top |

Uses | Printing, sign, billboard substrate | Cabinet, furniture in humid environment, wall panel | Same as PVC celuka board |

There are no good or bad between the three types of PVC foam board. But because of the different production process, they have different appearance and performance. Taking full advantage of their different properties, we can find the most suitable material for our application.

- Unlock Your Vision, Let's Create Together!

- CONTACT NOW

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.