Which Improper Packaging Causes Damage to PVC Foam Sheet?

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Aug 22,2022

Summary

In international shipping, poor packaging often causes damage to PVC foam board. In this blog, we will sort out the damage caused by improper packaging to PVC foam board.

In a previous blog, we shared What Are the Packaging Methods of PVC Foam Board?

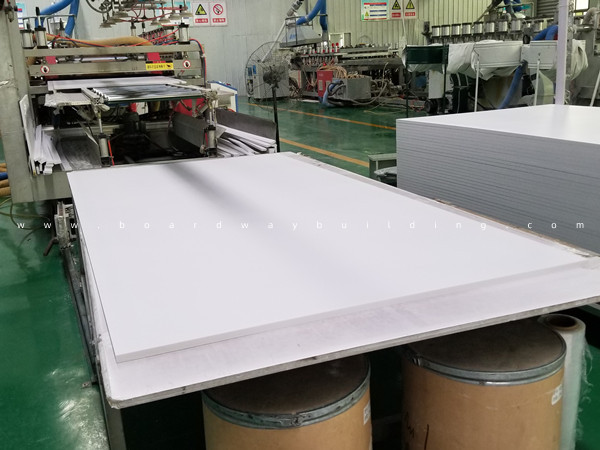

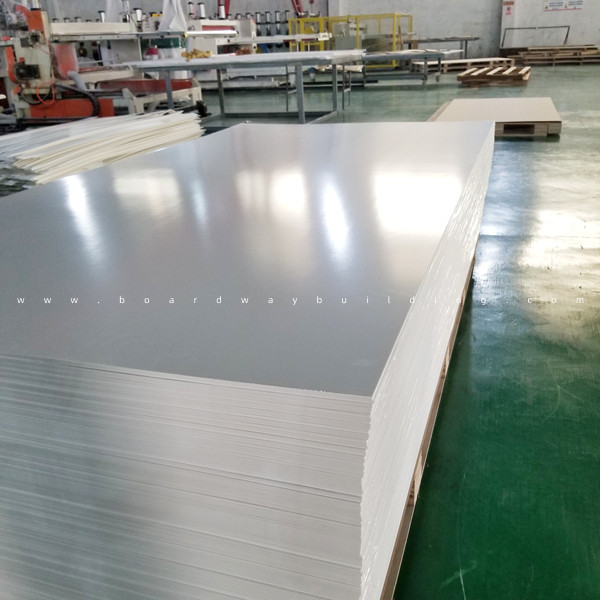

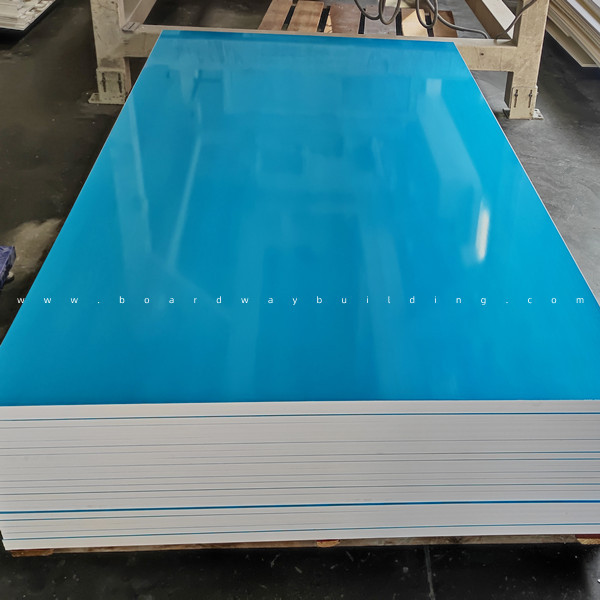

Our recommended and commonly used packaging materials for PVC foam board include PE bags, cartons, plywood pallets, and wooden cases. When packaging PVC sheets, it is also necessary to combine auxiliary packaging materials such as protective film, stretch film, cardboard corner protector, PP packing strap, and protective plate to complete the packaging.

Good packaging can well protect the goods from being transported to the destination in good condition. However, poor quality packaging materials or improper packaging methods will cause damage to the PVC foam board during transportation. Let's take a look at what may be inappropriate when packaging PVC foam board? What kind of damage will it cause to the PVC foam board? By understanding these details, we can try to avoid poor packaging, so as to better protect the PVC foam board during transportation.

What are the improper packaging of PVC foam board?

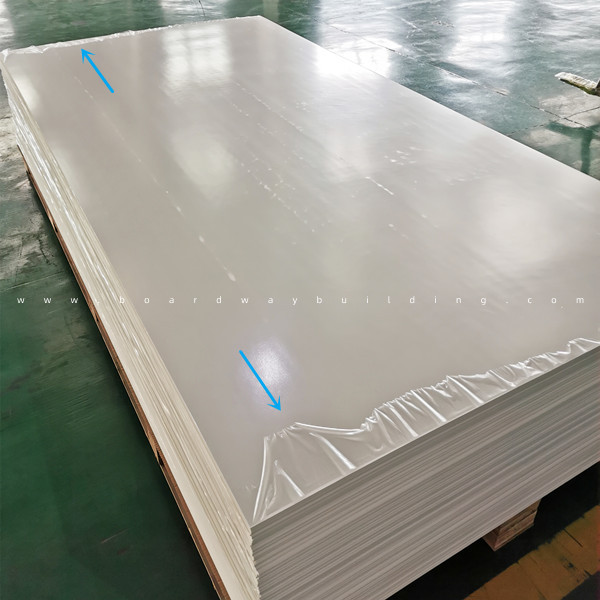

Insufficient viscosity or incomplete coverage of protective film.

The protective film is divided into two types: electrostatic film and adhesive film, that is, the protective film is attached to the PVC sheet by static electricity or glued to the PVC sheet. When the adhesion of the protective film is insufficient, it is very likely that the protective film on the next board will be taken along when the board is lifted.

If the PVC sheet is not completely covered with the protective film, the processing and handling will easily cause scratches on the surface that is not covered by the protective film.

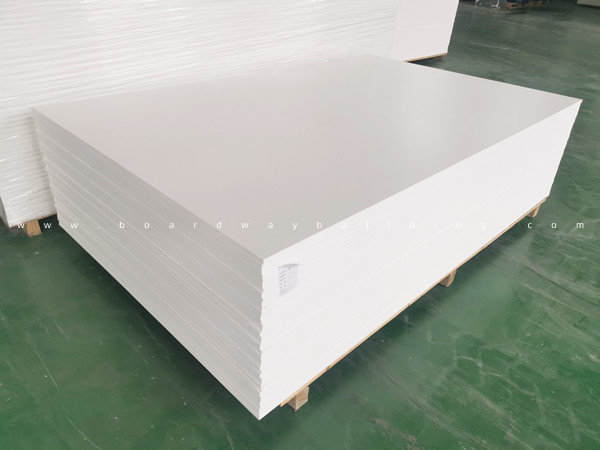

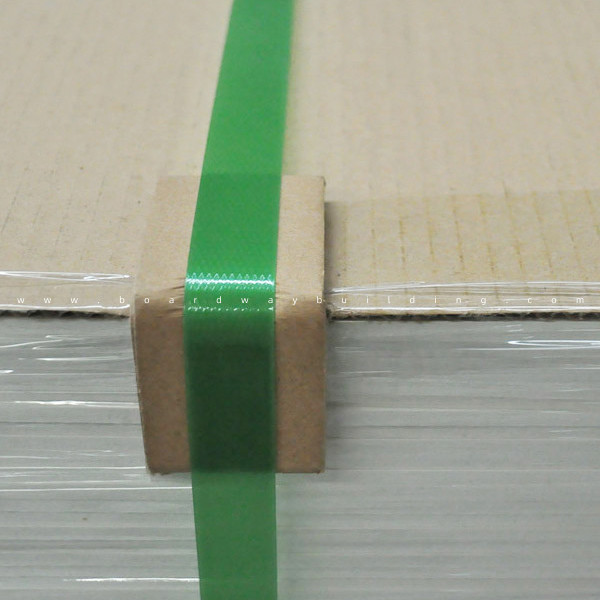

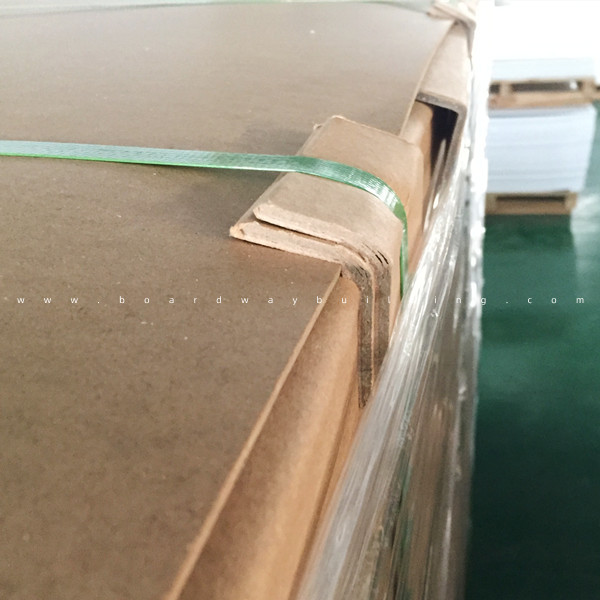

No cardboard corner protector to protect the four corners of the board.

Compared with the surface of the PVC foam sheet, its four corners may be more vulnerable. Any corner of the PVC foam board is not well protected, as long as the workers do not operate properly during loading and unloading, the goods may be damaged. Secondly, it is inevitable that the goods will shake during transportation. They may collide with each other and cause damage to the four corners of the board.

Therefore, whether it is packaged in PE bags or pallets, be sure to wrap the four corners of the board with cardboard corner protectors.

The carton is damp or the cardboard is too thin.

When packing PVC foam boards with damp cartons or cartons with too thin cardboard, it cannot help the goods resist collision. Such a carton itself is easily damaged and has little protection effect on the board. Also, there is a risk of damp cartons that the yellow color of the cardboard may penetrate into the PVC foam board, making it difficult to remove.

Therefore, if using a carton to pack PVC foam board, it is best to use a 5-layer corrugated cardboard carton, and make sure that the PVC foam board is covered with a protective film.

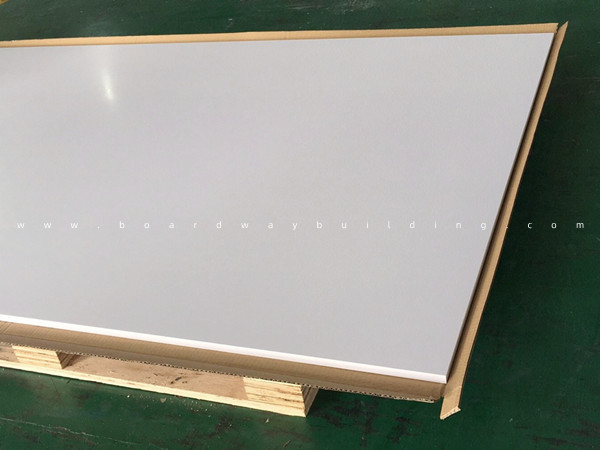

Insufficient bearing capacity of plywood pallets.

Plywood pallets with different structures and materials will have different bearing capacities even if the pallets are of the same size.

After the weight of the goods per pallet is determined, it must be packed with plywood pallets with sufficient bearing capacity, so as to avoid damage to the PVC foam board caused by the damage of the pallets when the goods are moved or stored.

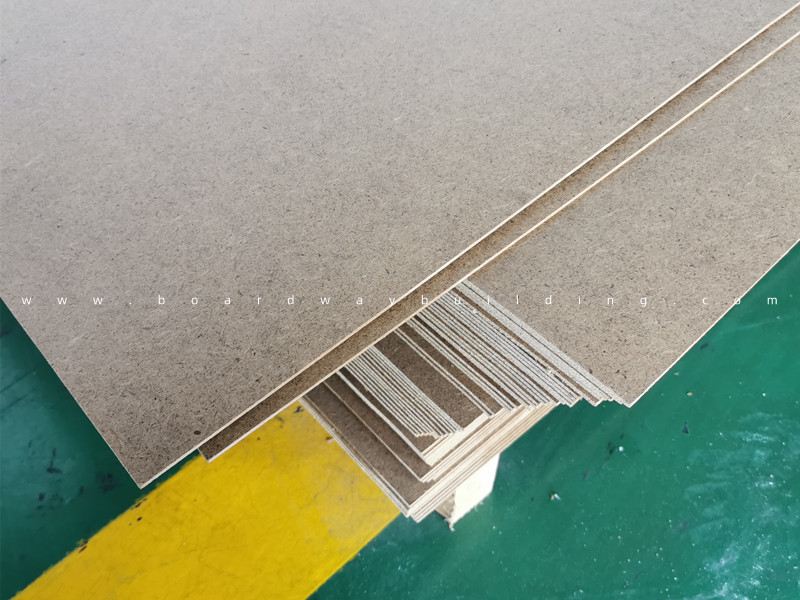

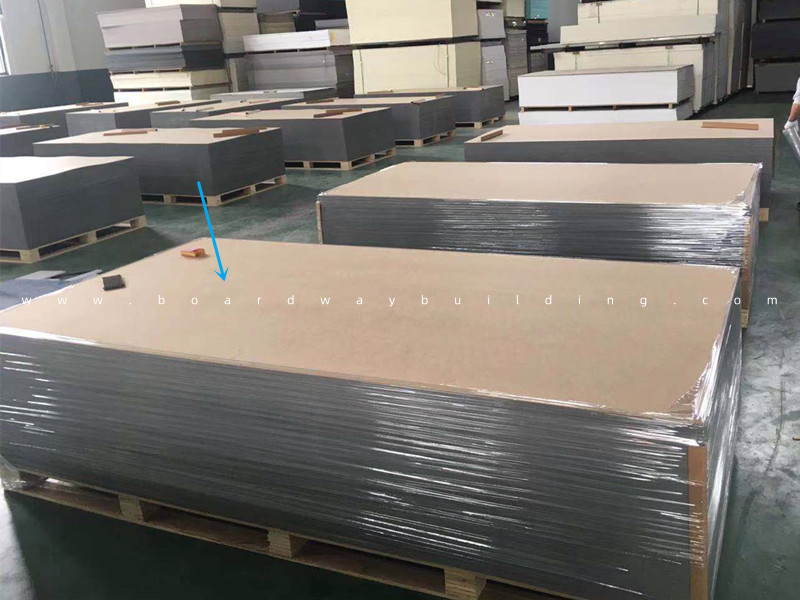

No protective panels are placed on the pallet and on the PVC sheets.

The protective panel can be a sturdy cardboard or a wooden board. Our factory uses MDF.

Generally speaking, we will put a protective panel on the pallet before stacking the PVC sheets. The purpose is to protect the PVC foam sheet from being scratched by the barbs or screws protruding from the pallet. In addition, placing a protective panel on the top of the PVC sheet is particularly important for pallet delivery. When LCL, the forwarder may stack other bulk cargos on top of our pallets. It is necessary to add a protective panel to avoid being crushed by other cargos.

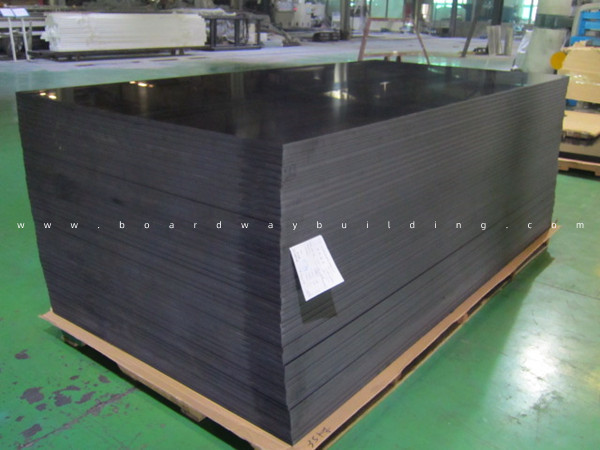

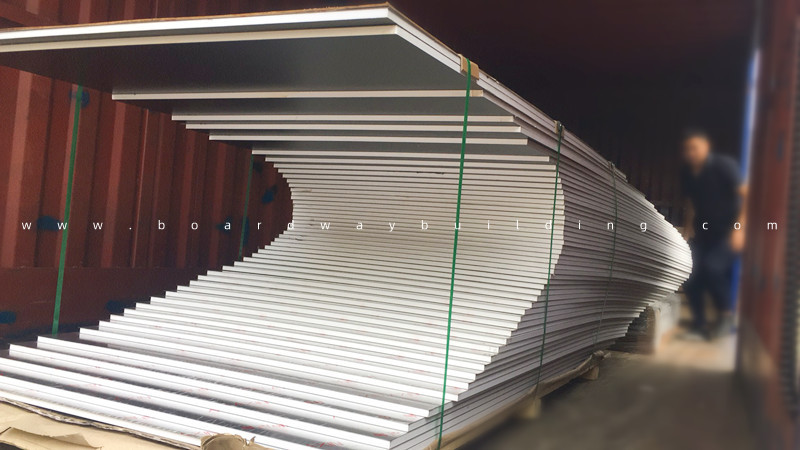

PP packing strap should be criss-crossed.

If not, the following will occur.

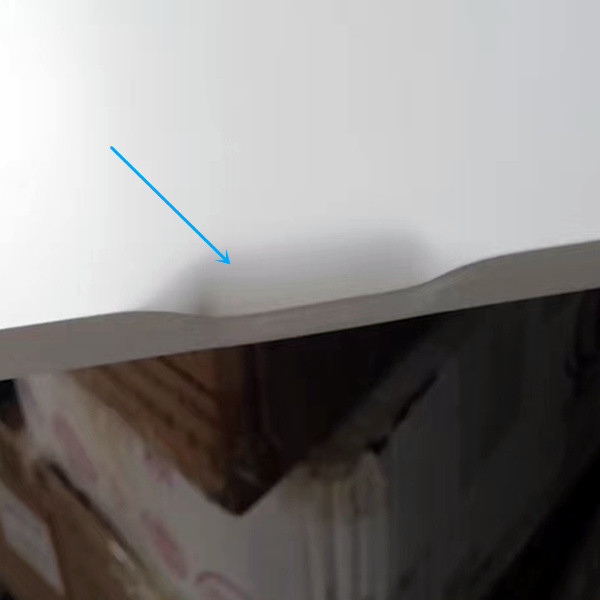

There is no reinforced protection under the PP packing straps.

The function of the PP packing strap is to tie the goods together with the pallet. However, during transportation, the shaking of the vehicle can easily cause the packing straps to be pulled and strangle the PVC foam sheet. It is important to use cardboard corner protectors for added protection. As far as our factory is concerned, we will put at least 2 corner protectors under the PP packing strap to strengthen the protection to ensure that the PVC sheet is not strangled by the packing strap.

Customized products should be packaged according to the actual situation.

The packaging demonstrations shared above are based on standard size PVC sheets. However, our company provides customers with customized processing services for plastic sheets. Customized products often have irregular shapes or are printed on the surface, which requires us to give it extra protection. Therefore, we also often customize packaging for our customers' products.

For example, the picture on the right shares a custom sample we made for our customers. This design has some small, pointed edges. When we are packing, the space inside the carton leaves room for the product to shake during transportation in the carton. In the end, the sample received by the customer is such an incomplete product.

After receiving the feedback, we re-made samples to the customer as quickly as possible. We are very grateful to the customer for giving us a second chance, and now we have worked with her many times.

Boardway has extensive experience in producing and exporting PVC foam board.

The experience of failure teaches us. We know which inappropriate packaging methods can cause damage in different situations. We also know very well how packaging is best for the product. In order to ensure that the products can be delivered to customers in good condition, we will continue to learn and become better.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.