Technical Data Sheet (TDS) of PVC Foam Board

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Nov 8,2022

Summary

Share the technical data test report of PVC foam board. Click the blog to learn more.

This blog shares some test reports on technical data of our PVC foam board (Tested by SGS Laboratory). We think that these data may be able to provide reference help for some users who are concerned about the technical data of PVC sheets. If you want to know more or want to get a quotation for PVC foam board, please feel free to contact us.

Sample Specifications:

Test Sample | Sanded PVC foam board | ||

|

Product Type

|

PVC celuka board

|

||

Quality Grade | Standard | ||

|

Thickness

|

12mm (before sanding)

|

||

|

Density

|

0.65g/cm3 (before sanding)

|

||

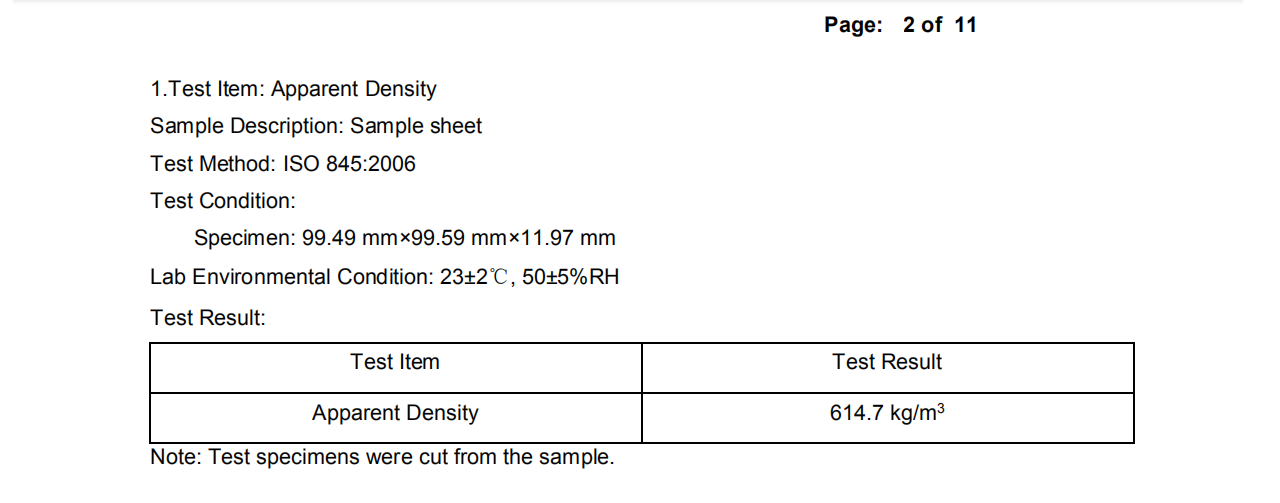

Apparent Density

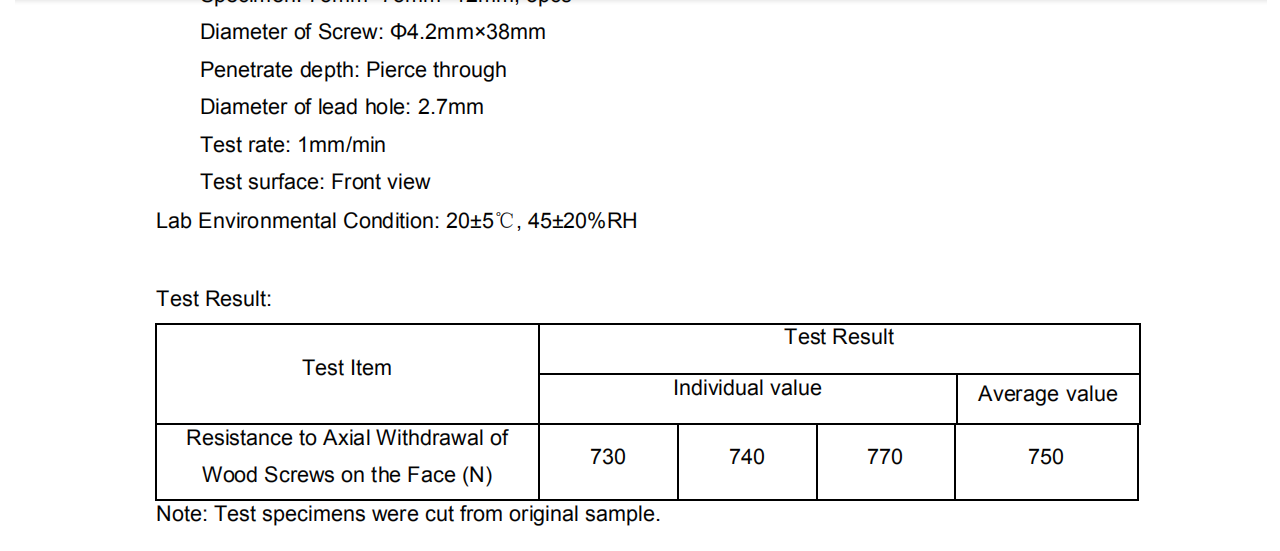

Resistance to Axial Withdrawal of Wood Screws on the Face

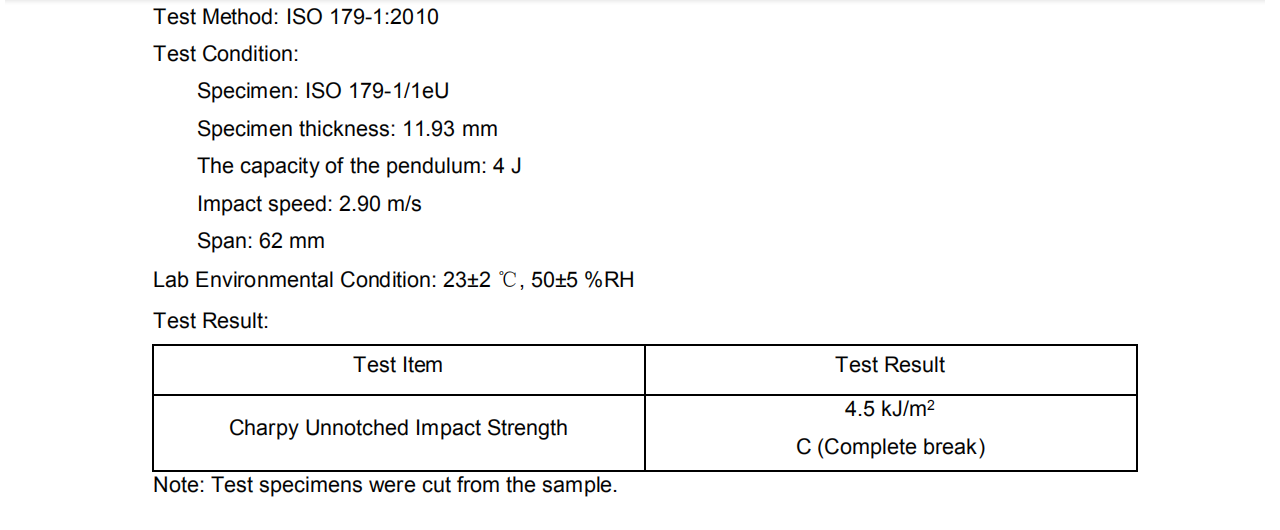

Charpy Unnotched Impact Strength

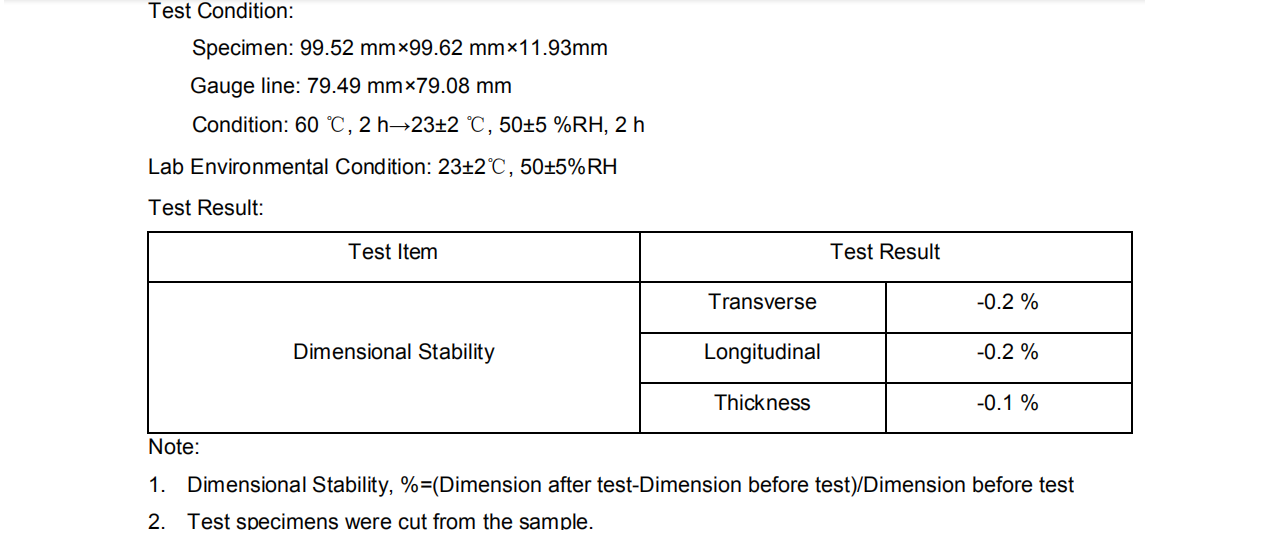

Dimensional Stability

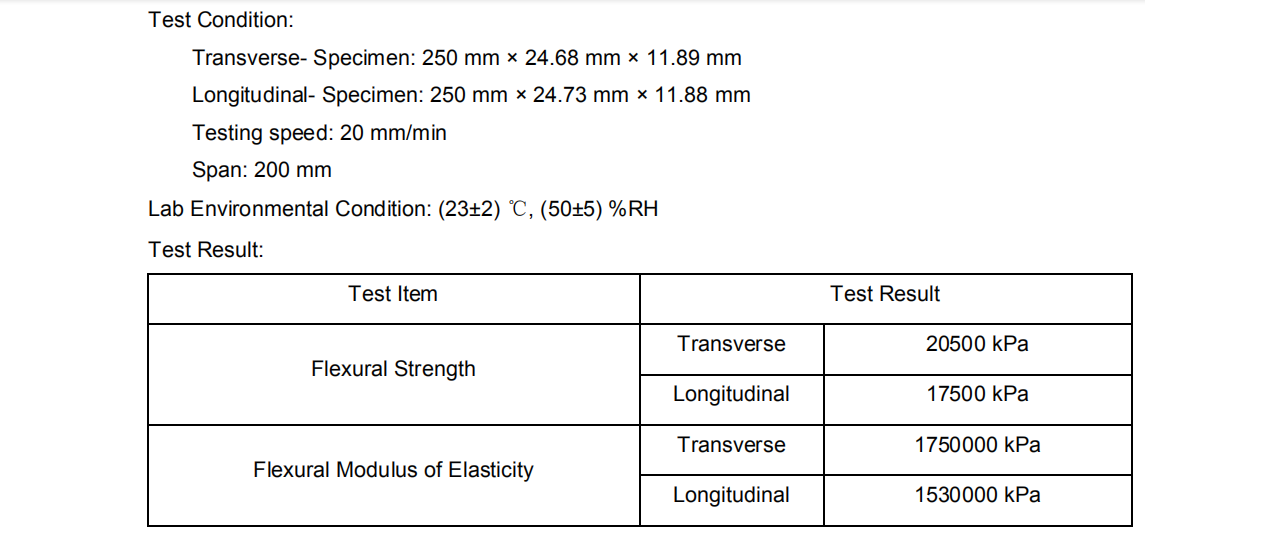

Flexural Strength and Flexural Modulus of Elasticity

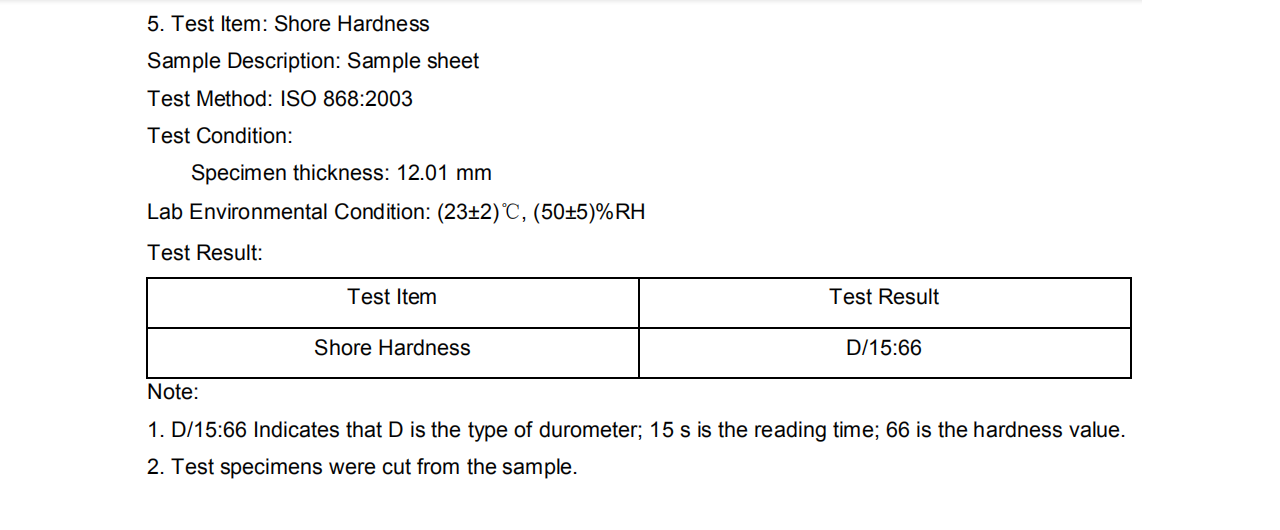

Shore Hardness

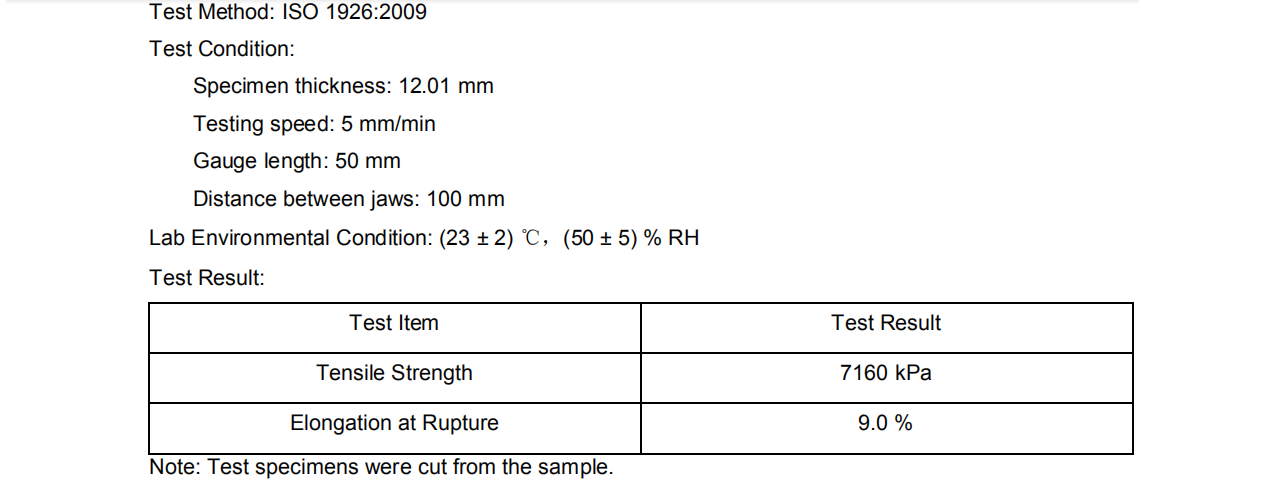

Tensile Strength and Elongation at Rupture

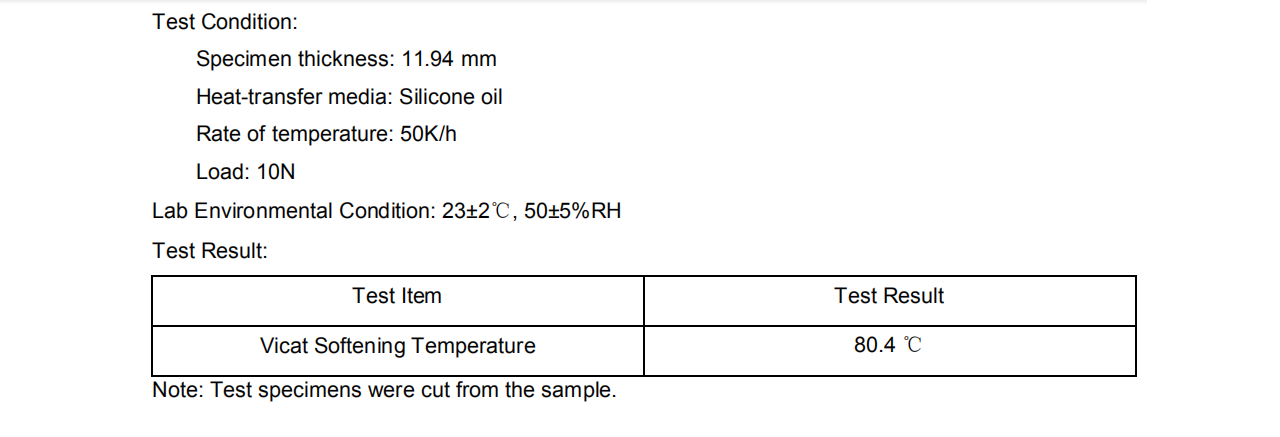

Vicat Softening Temperature

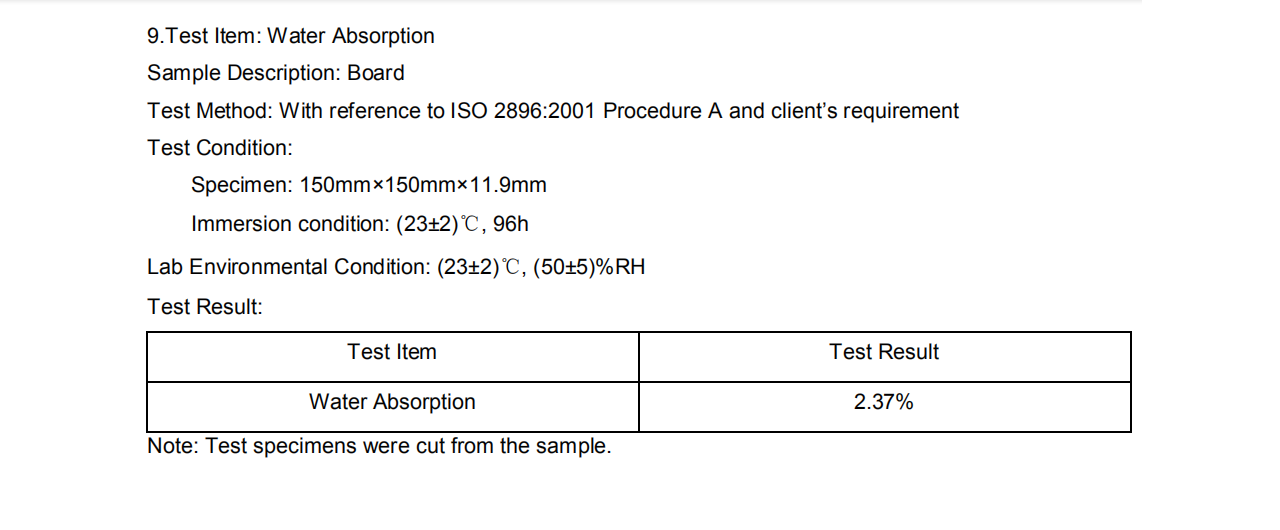

Water Absorption

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued