What Are the Characteristics of Expanded PVC?

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Jun 20,2023

Summary

Expanded PVC is a lightweight thermoplastic material that is foamed and extruded from polyvinyl chloride (PVC) with the help of heat and a foaming agent. Click to learn its ten characteristics!

What is Expanded PVC?

Expanded pvc also known as foamed PVC, is a lightweight thermoplastic material that is foamed and extruded from polyvinyl chloride (PVC) with the help of heat and a foaming agent. It is lightweight yet has a high strength-to-weight ratio, making it easy to handle while maintaining structural integrity. With its weather and chemical resistance, it can withstand moisture, UV radiation and temperature fluctuations, making it durable for indoor use and also suitable for outdoor applications. Expanded PVC is easy to manufacture and comes in a variety of colors, allowing for customization and versatility. Its smooth surface allows for excellent printability, providing vivid and detailed prints. Additionally, expanded PVC requires minimal maintenance and exhibits a balance of rigidity and flexibility, making it a popular choice for signage, displays, furniture, decor, architecture, and a variety of creative projects.

10 Characteristics of Expanded PVC

1. Lightweight: Expanded PVC is exceptionally lightweight thanks to its cellular (closed-cell foam) structure, which incorporates tiny air bubbles throughout the material. This feature makes it easy to handle, transport and work with, making it a breeze for workers during installation or fabrication.

2. High Strength-to-Weight Ratio: Despite its lightweight nature, expanded PVC boasts a remarkable strength-to-weight ratio. It offers excellent structural integrity and durability, allowing it to withstand various external forces and impacts. This characteristic makes it suitable for applications where strength is required without adding excessive weight.

3. Rigidity and Flexibility: Expanded PVC strikes a balance between rigidity and flexibility. It is rigid enough to maintain its shape and provide stability, making it suitable for structural applications. However, it also possesses a certain degree of flexibility, enabling it to be bent or formed into curved shapes without cracking or breaking.

Waterproof Test of Expanded PVC Foam Board

Bending Test of Expanded PVC Foam Board

Impact Test of Expanded PVC Foam Board

4. Weather Resistance: Expanded PVC demonstrates exceptional resistance to weather elements, making it a reliable choice for outdoor applications. It is resistant to moisture, UV radiation, and temperature fluctuations, ensuring that it can withstand harsh environmental conditions without deteriorating, warping, or fading over time.

5. Chemical Resistance: Expanded PVC exhibits resistance to many chemicals, acids, and alkalis. This characteristic allows it to maintain its structural integrity and appearance when exposed to a wide range of chemical substances, making it suitable for applications that involve contact with corrosive materials or environments.

6. Flame Retardant: Expanded PVC is inherently flame retardant, and it has self-extinguishing properties. It also prevents the spread of fire with the addition of flame retardants. It complies with various fire safety standards, making it a preferred choice for applications where fire resistance is essential, such as in building materials and signage.

7. Excellent Printability: Expanded PVC provides a smooth and consistent surface, ideal for printing. It readily accepts a variety of printing techniques including screen printing, digital printing and vinyl applications. The material delivers vibrant colors, sharp details and high-resolution prints, making it popular for signage, display and advertising materials.

8. Ease of Manufacture: Expanded PVC is relatively easy to manufacture and can be processed using common tools and techniques. It can be easily cut, routed, drilled or shaped to meet specific design requirements. The material's flexibility and dimensional stability make it suitable for a variety of fabrication methods, enabling precise customization.

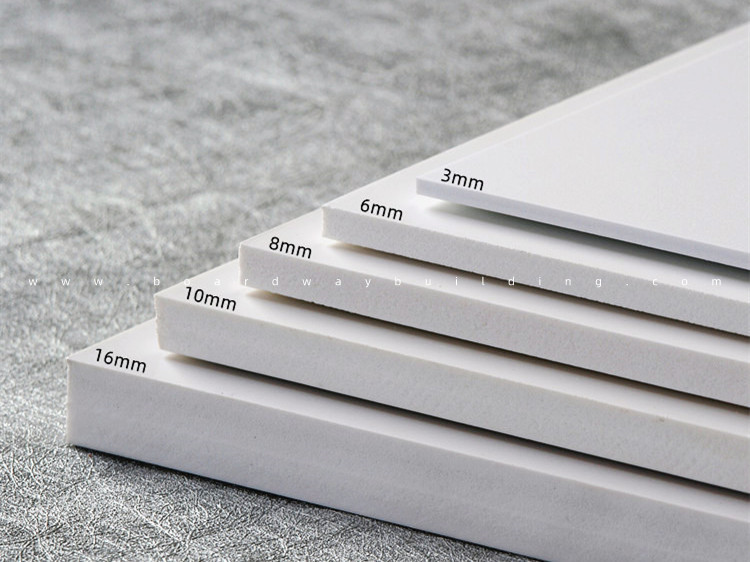

Expanded PVC Foam Sheet with Different Thicknesses

CNC Machining of Expanded PVC Foam Sheet

Lamination of Expanded PVC Foam Sheet

9. Wide Color Range: The common expanded PVC is mainly white, and it is available in a variety of colors, offering versatility in design choices. Whether you prefer vibrant and bold hues or subtle and muted tones, you can find expanded PVC in various color options to suit your aesthetic preferences and project requirements.

10. Cost-effective and Low Maintenance: Compared to materials like wood, metal, or acrylic, expanded PVC is often considered cost-effective. While the exact cost comparison may vary depending on factors such as location and specific project requirements, expanded PVC generally offers a more budget-friendly option. It is typically less expensive than materials like metal or acrylic, which can be costly due to their production processes and raw material costs. Additionally, expanded PVC requires less maintenance and is easier to work with, potentially reducing labor and installation costs. Its durability and weather resistance also contribute to cost savings over time as it may require fewer repairs or replacements.

These detailed characteristics make expanded PVC a versatile material with a wide range of applications including signage and displays, furniture, decor, construction, model making, and more. Its lightweight properties, strength, weather resistance, printability, cost-effectiveness and ease of fabrication have made it popular among designers, builders and creative enthusiasts.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.