What Is the Difference Between Expanded PVC and PVC?

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Jun 25,2023

Summary

PVC and expanded PVC share similar chemical composition and properties, the differences in structure, density, rigidity, thermal insulation, and processing make them suitable for distinct applications.

Expanded PVC VS PVC

Expanded PVC and PVC are both thermoplastic materials made of polyvinyl chloride as the main raw material, but they have different properties, characteristics and uses.

PVC, also known as rigid PVC or solid PVC, is a durable, rigid plastic material. It is widely used in various industries due to its excellent chemical resistance, strength and durability. PVC is commonly used in applications such as pipes, fittings, window frames and electrical insulation.

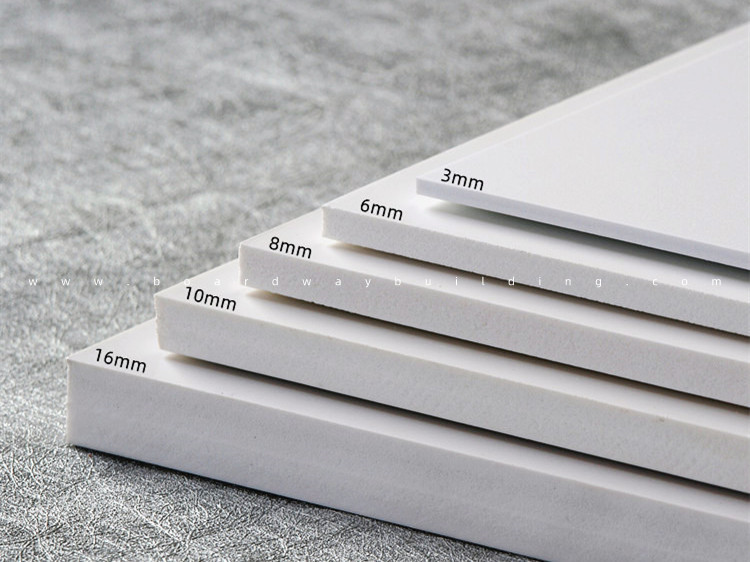

Expanded PVC, on the other hand, is a foamed version of PVC in which a foaming agent is added during its manufacture to expand it and form a cellular core structure filled with tiny air bubbles. This foaming process gives expanded PVC its lightweight nature while still maintaining its strength and rigidity. Expanded PVC is commonly known as foam PVC or PVC foam board. It is available in sheets of various thicknesses and sizes for use in signage, displays, furniture, decorating, model making and construction industries.

Difference between expanded PVC and PVC

1. Rigidity: PVC is known for its rigidity and strength, making it suitable for structural applications. On the other hand, expanded PVC has a lower rigidity due to the presence of air cells. While still providing good strength and stability, expanded PVC is more flexible and somewhat less rigid than solid PVC.

2. Lightweight: PVC has a higher density and is heavier compared to expanded PVC. The foaming process reduces the density of expanded PVC, making it significantly lighter. This property makes expanded PVC easier to handle, transport, and work with in various applications.

3. Flexibility: PVC is relatively less flexible, while expanded PVC has a certain degree of flexibility. This flexibility allows expanded PVC to be bent or shaped into curved forms without cracking or breaking.

4. Impact Resistance: PVC has better impact resistance than expanded PVC. Its solid structure provides more resistance to external forces, making it suitable for applications where impact resistance is critical.

5. Thermal Insulation: The cellular structure of expanded PVC provides inherent thermal insulation properties. The air bubbles trapped within the material act as insulating barriers, making expanded PVC more effective at resisting heat transfer than solid PVC.

6. Weather Resistance: Both PVC and expanded PVC offer good weather resistance. They can withstand exposure to UV radiation, moisture, and temperature fluctuations without significant degradation. However, the specific additives and formulations used in each material can affect their weathering performance.

PVC: Due to its rigid nature and high strength, PVC is commonly used in applications that require structural stability and durability. It is widely used in the construction industry for pipes, fittings, window frames, and roofing membranes. PVC is also used in electrical insulation, automotive components, and other industrial applications.

Expanded PVC: Expanded PVC, with its lightweight and versatile characteristics, finds application in various industries. It is commonly used in signage, displays, model making, exhibition stands, interior design elements, and advertising boards. Its excellent printability, ease of fabrication, and cost-effectiveness make it a popular choice for visual communication and creative projects.

PVC excels in structural rigidity and impact resistance, making it suitable for applications that require strength and durability. On the other hand, expanded PVC offers the advantages of being lightweight, flexible, and easy to work with, making it a preferred choice for applications where weight, ease of handling, and customization are important factors. The specific performance and application requirements will determine which material is the most suitable for a given project.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.