How to Properly Cut, Shape, and Finish PVC Foam Board

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Sep 12,2024

Summary

Discover expert techniques for cutting, shaping, and finishing PVC foam board. Boardway, a trusted Chinese manufacturer with 18 years of experience, offers customized solutions for all your PVC foam board needs.

PVC foam board is a lightweight yet durable material that has become popular across various industries, including signage, construction, and advertising, due to its versatility and ease of use. Whether you' re crafting detailed designs or working on large-scale projects, PVC foam board offers an excellent combination of flexibility and strength. With 18 years of experience, Boardway, a leading China-based manufacturer, specializes in providing high-quality PVC foam boards. Our expertise ensures that customers receive materials tailored to their specific needs, with customizable options and a range of thicknesses to suit any project.

1. Choosing the Right Tools for Cutting

Selecting the right tools for cutting PVC foam board is essential to achieving clean, precise cuts without damaging the material. The choice of tools largely depends on the thickness of the board and the level of precision required for your project.

Manual Cutting

For thin PVC foam boards (1mm–5mm), manual cutting is often sufficient and can be done using basic tools such as utility knives or hand saws. These tools are especially suited for smaller DIY projects, signage, or craft applications where detailed and delicate work is required.

Safety Tip: When cutting manually, always ensure you're working on a stable surface, and wear protective gloves and eyewear to prevent injury.

Mechanical Cutting

For medium to thick PVC foam boards (6mm–30mm), mechanical cutting tools are recommended to ensure accuracy, efficiency, and smoother edges.

Pro Tip: Always ensure that the blade being used has fine, closely spaced teeth to avoid rough or jagged edges. Additionally, adjust the machine settings according to the thickness of the board to prevent overheating or melting.

2. Shaping PVC Foam Board

Shaping PVC foam board opens up a wide range of creative and functional possibilities, whether you' re designing intricate signage, architectural elements, or creating curved surfaces. The shaping method you choose depends on the thickness of the board and the complexity of the design. Here are three common techniques for shaping PVC foam board:

Heat Bending

Heat bending is an effective method for creating curves and rounded shapes in medium-thickness PVC foam boards (6mm–10mm). By applying heat, the board becomes soft and pliable, allowing you to mold it into various forms.

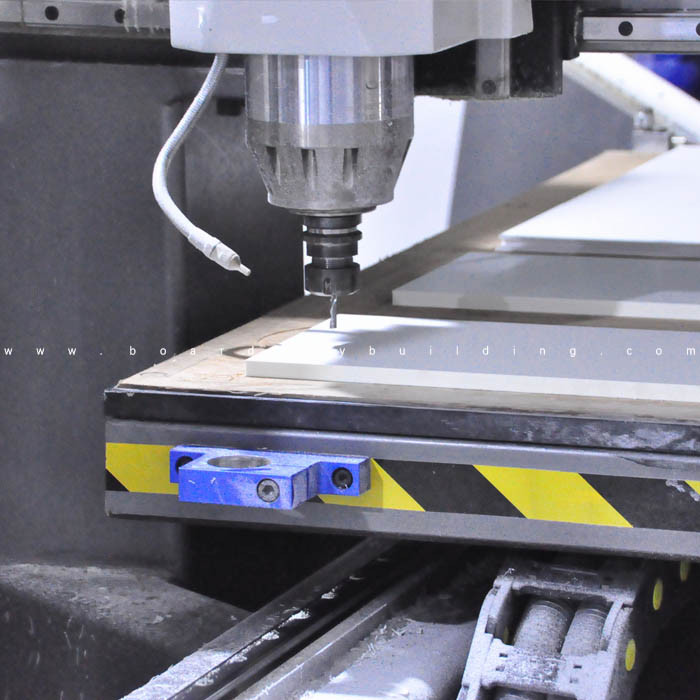

CNC Shaping

For more intricate and detailed designs, CNC shaping is the most precise and efficient method. CNC routers can be programmed to cut and shape PVC foam board into complex patterns or designs with high precision, making them ideal for custom projects that require fine details.

Cold Bending

Cold bending is a simpler technique used primarily for thin PVC foam boards (up to 5mm thick). These boards can be bent without the need for heat, but the process requires additional support to help the board retain its shape.

By understanding the different shaping techniques, you can choose the most suitable method for your project' s specific requirements. Whether you need smooth curves, intricate designs, or simple bends, Boardway provides the expertise and customization services to bring your vision to life.

3. Finishing PVC Foam Board

Finishing PVC foam board properly ensures that it not only looks professional but also maintains its durability over time. Depending on your project, whether it' s a signage application, display, or construction element, choosing the right finishing techniques can significantly improve the aesthetics and longevity of the board.

Sanding

After cutting PVC foam board, sanding is a crucial step to achieve smooth edges and surfaces. This is especially important when the board will be used in applications where the edges are visible or where you plan to apply paint or graphics.

Tip: Handle the board carefully during sanding to prevent accidental dents or scratches, particularly on thinner boards, as they can be more delicate.

Painting and Printing

PVC foam board is highly versatile when it comes to surface finishes like painting and printing. It' s compatible with a range of paints and printing techniques, allowing for vibrant, professional-quality results.

Boardway' s Custom Printing Services: At Boardway, we offer custom printing options for PVC foam boards, ensuring that your designs are printed with precision and clarity, whether for indoor or outdoor use.

Sealing and Edging

For outdoor applications or projects that require enhanced durability, sealing the PVC foam board' s surface and edges can help extend its lifespan.

By carefully finishing your PVC foam board, whether through sanding, painting, printing, or sealing, you' ll not only improve the aesthetics of your project but also ensure that the material lasts longer and performs better in its intended application.

4. Pro Tips for a Perfect Finish

To achieve a flawless finish with PVC foam board:

These tips will help you achieve professional, durable results for your projects.

In conclusion, using the proper tools and techniques for cutting, shaping, and finishing PVC foam board is crucial for achieving professional-quality results. By following the best practices outlined in this article, you can enhance both the appearance and durability of your projects.

With 18 years of manufacturing experience, Boardway is a trusted Chinese supplier of high-quality, customizable PVC foam boards for a wide range of applications. Whether you need precise cuts, intricate shapes, or custom finishes, we' re here to provide tailored solutions to meet your needs.

For more information or to inquire about custom orders, feel free to contact Boardway today!