Frequently Asked Questions about Laminated PVC Foam Board

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Oct 18,2022

Summary

Have you ever had these questions about laminated PVC foam sheet? Such as its performance, safety, service life, etc. Let's find answers to some frequently asked questions from our customers.

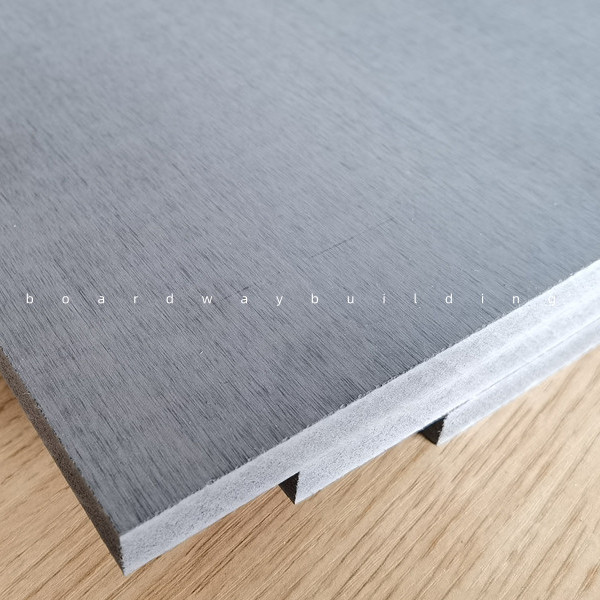

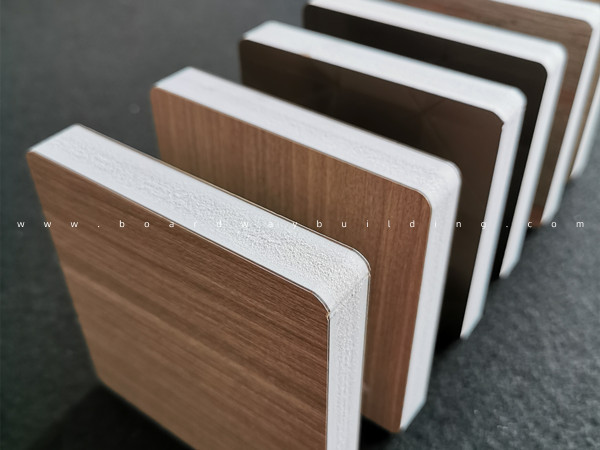

Laminated PVC foam sheet is a building material with a PVC foam sheet or WPC foam sheet as the substrate, and a thin surface material is adhered to its single surface or both surfaces.

We often provide customers with various types, styles and specifications of laminated PVC foam sheets. For customers who are new to it, there will always be many questions. So, we put together these common questions to share with interested friends. What did the customer ask? How did we answer?

How does the laminate hold up to the PVC board? Will it hold overtime and not peel off?

The lamination process is done on our lamination production line. The substrate (PVC foam board) and the surface material are glued together by PUR hot melt adhesive. PUR hot melt adhesive is currently one of the most widely used adhesives in the building materials industry. It has excellent adhesive strength, water resistance and aging resistance.

In order to have a better lamination effect, the thickness tolerance of PVC foam board should be within ±0.1mm. For us, for PVC sheet with a thickness of less than 15mm, we can make the thickness tolerance within the range. If the thickness of the board exceeds 15mm, our solution is to sand the PVC foam board through a sanding machine first, and then proceed to the lamination process. Sanding can even out the thickness of the PVC sheet. The resulting laminate will be flatter and last longer. Therefore, the lamination cost of thick substrates is higher due to the additional sanding process.

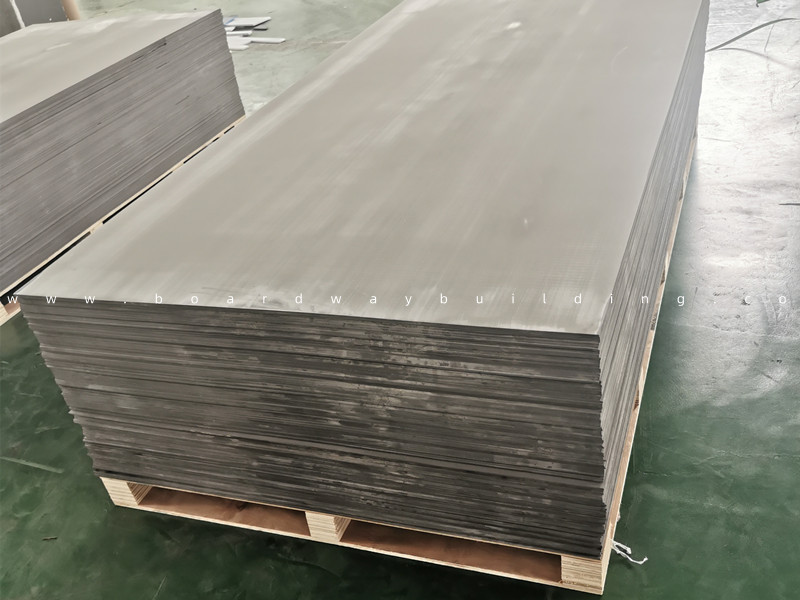

For our manufacturer, to control the thickness of the PVC sheet, the quantity is the key. The number of PVC sheets produced at a time should be large enough. If 1000 sheets are produced, their thickness uniformity will definitely be better than if only 100 sheets are produced. This is because the operation of the production machine has not yet fully stabilized in the first 10 hours after start-up. We keep adjusting the machine until the PVC foam board becomes stable. So if there are only 100 sheets to be produced, they are all produced in less than 10 hours after starting up. Thickness tolerances for these boards may be within ±0.3mm. In short, more quantity allows better quality control.

How does the laminate do against scratching? Is it strong and be able to resist deep starches?

If you have high requirements for scratch resistance of the surface material, you may choose a surface material with a scratch-resistant treatment layer. As for whether the scratch resistance can meet your requirements, it is best to take samples for testing before bulk orders, and we are very happy to provide you with samples. In addition, the scratch-resistant film is customizable, it has different scratch-resistant grades and can be customized according to your needs.

How's the performance of laminated PVC foam board in the cold winter and the hot summer?

For surface materials, there are different requirements for outdoor or indoor use. If the PVC laminate is not weather resistant, it is not recommended for outdoor use. Our products are suitable for temperatures ranging from 113 °F to -4 °F. PVC foam boards, like other plastics, become brittle at low temperatures. As long as it is not intentionally damaged and used in good assembly, it's usually fine. As for the glue, the adhesive strength can be maintained for a long time without being directly exposed to the sun. The picture below shows our company kitchen cabinets. Cabinet doors are made of laminated PVC foam board. We have used it for 7 years and everything is fine.

What is the color consistency with the laminates, will they always be the same?

If the product is used indoors without direct sunlight, the color will not change significantly. However, if the product you purchase is not specifically designed for outdoor use, we cannot guarantee that the color will remain unchanged if it is always exposed to outdoor sunlight. Please consider the usage environment when purchasing laminated PVC foam board. In indoor use, there will be aging, but it is not easy to find. After 1-2 years of use, when you compare it with the original sample, you will find that it has turned yellow or gray, but the color still looks like the original color. If you do not compare it with the sample two years ago, you may not find how different it is.

Can you make the pattern of the laminated surface according to my designed drawings?

We recommend sending us your drawings first, we will find a design that is close to you and see if you can accept this similar design. In general, off-the-shelf laminates are easier to manufacture, more readily available from stock, and more affordable. However, if you want to customize the design of the surface material, it will cost you a high plate making fee and a huge order quantity to do it. (Data for your reference: the production capacity of one production line of the surface material factory is 120,000 square meters per day.) In short, we do not recommend customizing surface materials when the order quantity is not large.

What do you do with the waste from the CNC cuts? Are you able to recycle it? And are you able to reuse it?

Boardway respects green, environmental protection and sustainable concepts in production and products. Plastic products are a recyclable material. Waste from production lines and CNC cutting is recycled and reused in our factory. Of course we make sure that these recycled materials are reused without affecting the performance and appearance of the product. However, when the laminated PVC foam board is recycled and reused, the surface material should be separated from the substrate, and then sorted and recycled according to different material types and different colors. Such recycling is difficult, and we usually ask professional recycling companies to handle it.

What is your maximum daily production capacity?

We have 8 production lines, each with a capacity of 8 tons per day, that is, we can produce 64 tons per day. Looking forward to your order, if your order quantity is very large, we will try our best to increase the production capacity for you.

For more information on Laminated PVC Board, please find

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

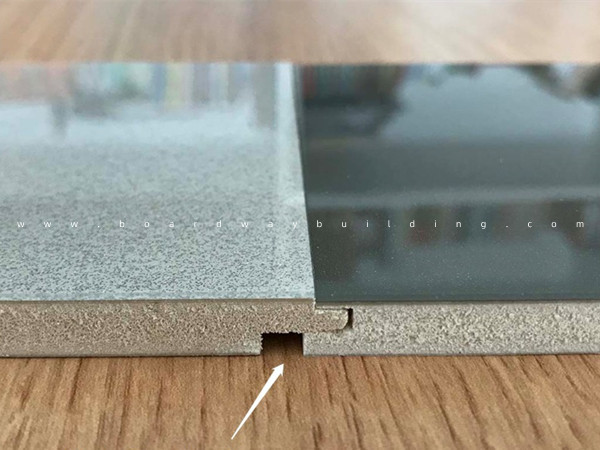

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued