Choosing the Right Formwork for Your Project: PVC Plastic Formwork vs. Plywood Formwork

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Dec 7,2023

Summary

Explore innovative construction solutions with Boardway's PVC Plastic Formwork, a durable and customizable alternative to traditional materials. Our PVC Foam Board for construction offers versatility and sustainability, providing a reliable choice for your project's formwork needs.

In the ever-evolving landscape of construction, the choice of formwork material plays a pivotal role in the success of any project. For those seeking a durable, versatile, and eco-friendly solution, the decision often boils down to PVC Plastic Formwork and Plywood Formwork. In this comprehensive guide, we will delve into the nuances of these materials, comparing their features, advantages, and disadvantages. Whether you're involved in residential, commercial, or industrial construction, understanding the intricacies of formwork options can lead to informed decisions that positively impact your project's efficiency and sustainability.

PVC Plastic Formwork vs. Plywood Formwork

Common Points:

1. Forming Capability: Both PVC plastic formwork and plywood formwork are versatile materials capable of creating various shapes and structures in concrete construction.

2. Reusability: Both materials are designed for multiple uses, contributing to cost-effectiveness over the long term.

3. Lightweight: PVC plastic formwork and plywood formwork are relatively lightweight, making them easier to handle and install compared to heavier materials like traditional steel formwork.

Differences:

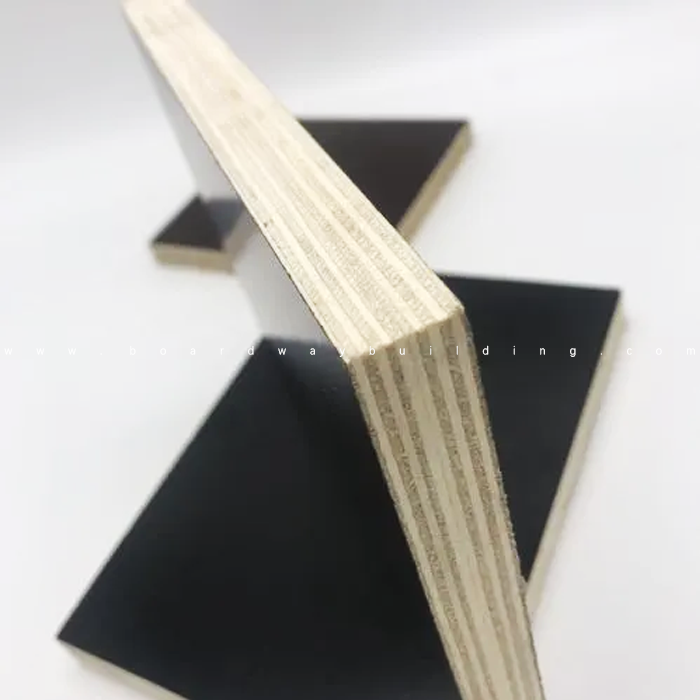

1. Material Composition:PVC Plastic Formwork: Made from Polyvinyl Chloride, a type of plastic known for its durability and resistance to moisture and chemicals. Plywood Formwork: Composed of layers of wood veneers glued together, typically made from hardwood or softwood.

2. Durability:PVC Plastic Formwork: Resistant to moisture, chemicals, and UV radiation. It doesn't rot or warp over time. Plywood Formwork: Vulnerable to water damage, especially if not properly sealed or if exposed to prolonged moisture.

3. Surface Finish:PVC Plastic Formwork: Provides a smooth surface finish to the concrete, reducing the need for additional finishing work. Plywood Formwork: May require additional finishing work to achieve a smooth surface.

4. Weight and Handling:PVC Plastic Formwork: Generally lighter than plywood, making it easier to handle and transport. Plywood Formwork: Slightly heavier than PVC, but still lighter than traditional steel formwork.

5. Environmental Impact:PVC Plastic Formwork: May raise environmental concerns due to the use of plastic, but its higher number of reusable cycles can offset some of these concerns. Plywood Formwork: Considered a renewable resource, but the production process involves cutting down trees, impacting ecosystems.

Advantages and Disadvantages:

PVC Plastic Formwork:

Advantages:

✔ Resistant to moisture, chemicals, and UV radiation.

✔ Smooth surface finish reduces the need for additional finishing.

✔ Lightweight and easy to handle.

✔ Reusable, with a higher number of cycles, contributing significantly to cost savings and reduced environmental impact. Ideal for projects with a need for frequent formwork reuse.

Disadvantages:

✔ Environmental concerns related to plastic use.

✔ May have a higher initial cost compared to plywood.

Plywood Formwork:

Advantages:

✔ Natural material with lower environmental impact.

✔ Well-established, widely used, and familiar in the construction industry.

✔ Can be cost-effective, especially for short-term or small-scale projects.

Disadvantages:

✔ Susceptible to water damage and deterioration

✔ May require additional finishing work for a smooth surface.

✔ Heavier than PVC, making handling and transportation more challenging.

Choosing the Right Formwork:

- Consider the specific requirements of your project, such as the desired surface finish, exposure to environmental elements, and the need for reusability.

- Evaluate the budget constraints and weigh the initial cost against long-term savings.

- Assess the environmental impact and choose the material that aligns with sustainability goals.

In the realm of formwork materials, the choice between PVC Plastic Formwork and Plywood Formwork is a decision that defines the trajectory of a construction project. As you embark on your journey to find the ideal formwork solution, consider Boardway, a leading PVC Plastic Formwork manufacturer based in China. At Boardway, we take pride in offering tailor-made solutions to meet your project requirements, including customized sizes and densities. Our commitment to quality, durability, and environmental sustainability sets us apart. Feel free to reach out to us for quotes and complimentary samples, and let Boardway be your trusted partner in building a future where formwork excellence meets innovation.

- Experience the Best in PVC formwork with Boardway

- CONTACT NOW