PVC concrete formwork, PVC concrete formwork for formwork systerm

- Model

- B - O CEL

Item specifics

- Provided Service:

- Cutting, Printing, CNC Engraving, Laminating

- Custom Work:

- Color, Width, Length, Size, Density, Packing

- Certificate:

- RoSH, REACH, Class A @ASTM-E84, Class B2/B1

Review

Description

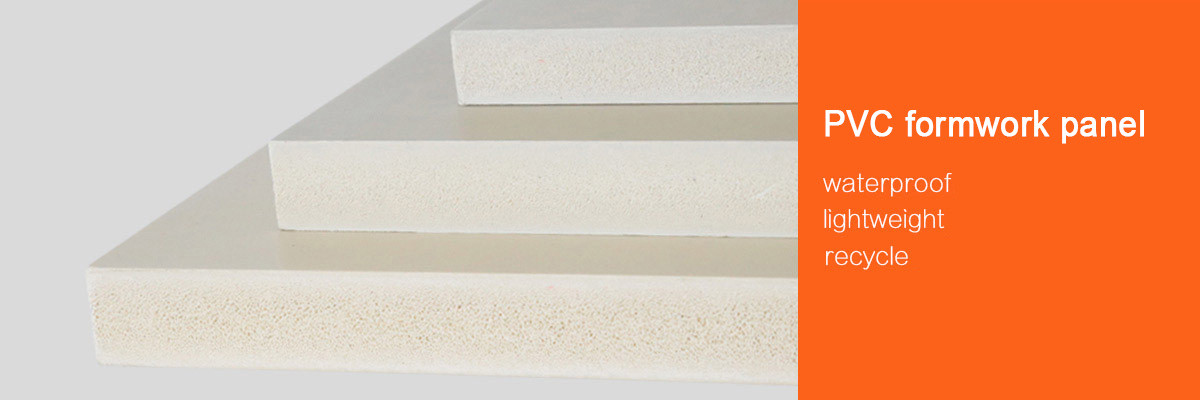

Boardway™ PVC formwork panel

lightweight & strong boards - PVC formwork panel

PVC Formwork Panel are available with various names like ‘Construction boards’, ‘Crust foam boards’, ‘PVC shuttering boards’, PVC Plates,PVC sheets, PVC panels, PVC formwork panels etc. in global markets. PVC formwork sheet is made by PVC resin and at a certain ratio, added with special additives and extruded at high temperature, with a special application, can be applied to the field of plywood processing. So far, it is the best environmental protection material to replace plywood formwork.

Features:

- Anti-UV

- Recycle.

- Flexible;

- Water-proof

- Easily cleaned.

- Low Flammability.

- Excellent Formability.

- Perfect Machinability;

- Lightweight, easily reassembled

PRODUCT AVAILABLE

| Thickness: | 10mm,12mm, 13mm, 14mm, 15mm, 17mm, 18mm |  | |||||||||||||||||||

| Width: | 915,1220 standard. Other width can be customized. | ||||||||||||||||||||

| Size: | 3'*6', 4'*8' 915*1830,1220*2440 standard. Other size can be customized. | ||||||||||||||||||||

| Colour: | Grey green | ||||||||||||||||||||

| Surface: | Smooth | ||||||||||||||||||||

| Density: | 0.68-0.8g/cm3 | ||||||||||||||||||||

MAIN FEATURES

Boardway™ PVC formwork panel are excellent alternative

to formwork Plywood

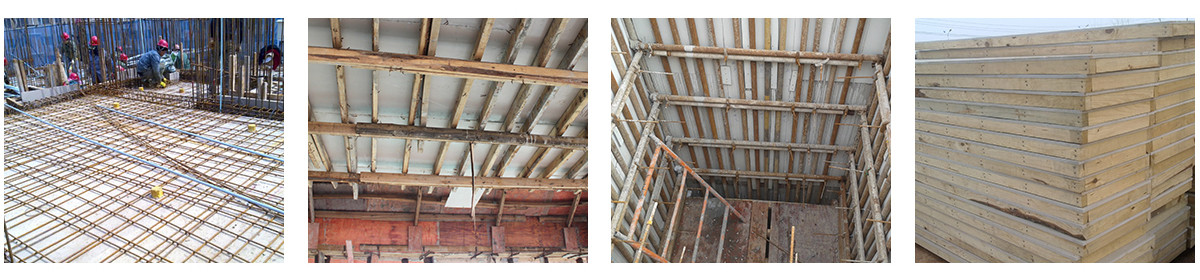

Our domestic projects

Our Thailand projects

Our Vietnam projects

What makes PVC Formwork Panel so popular nowadays? Why is it better than plywood?

| Comparison | PVC Formwork Panel | Plywood Formwork Sheet |

|  | |

| Recycled | ≥20 | ≤8 |

| Construction technology | can be sawed, nailed, drill, can be processed as plywood | has been popularized |

| Demould | Not need mould release agent, Convenient demoulding | Need mould release agent, also need to clear the surface |

| Connection | Tight assembling, Structured, surface smooth,which can meet the standard of as-cast-finish concrete | Easy to have warping deformation after 4 times recycle, bad thickness tolerence,which makes the deviation of building structure, Easy degumming , bubble, Crack;Difficult to handle when reassembled |

| Weather resistance | From minus 10 to up to 70, no shrinkage no deformation, Non expansive cracking | All kinds of weather |

| Water resistance | Water-proof | Not Water-proof, Easy to have warping deformation |

| Fire resistance | Self extinguishing | inflammable |

| Plasticity | Good plasticity, can be used for various type of construction part, such as cylinder, arc | No plasticity |

| Customization | Can customize according to project, which improves the efficiency | Not customizable, have to do fabrication on site, waste time and labor |

| Cutting ability | very good cutting ability, the edge is smooth after cutting | Bad cutting ability, have to use special saw |

| Environmental effect | Recyclable | Non-Recyclable |

More

FAQS

Q: What is the normal density using for the formwork sheet?

A: Here is some reference: 10mm 0.7g/cm3, 12mm: 0.68-0.75g/cm3, 15mm: 0.68-0.75g/cm3 ; 18mm: 0.7g/cm3.

Q: How is the main mateiral for this product?

A: PVC resin.

Q: Why this material is so expensive comparing with plywood?

A:Only compare the unit price, yes PVC formwork is expensive than plywood; but if you compare the total cost with and project quality, WPC formwork have more benefits, let's see an example.

Benefit: Actual cost saving

18mm both sides flimed plywood, unit price: $20, can use about 7-8 times, the price average is $2.5-2.85 each time

18mm PVC formwork sheet, unit price: $40, can use about 30-35 times, the price average is $1.33-1.1 each time

Q How many times can PVC formwork sheet recycle?

A: Depend on how you use it, if you fit the board on a structure and use it for a while, the max so far from one of our Thai customer;sproject is 52 times each side; if you cut it and use it as a strip following with the right instruction, each side can be recycle around 20 times.

More

Further infomration on Building Board