What Are the Pros and Cons of PVC Formwork?

- Share

- From

- www.boardwaybuilding.com

- publisher

- Boardway

- Issue Time

- Nov 27,2023

Summary

Explore the advantages and disadvantages of PVC formwork for construction projects. Discover its various applications and make informed decisions for your specific needs. Boardway, a leading Chinese supplier, offers high-quality PVC formwork solutions tailored to your construction requirements.

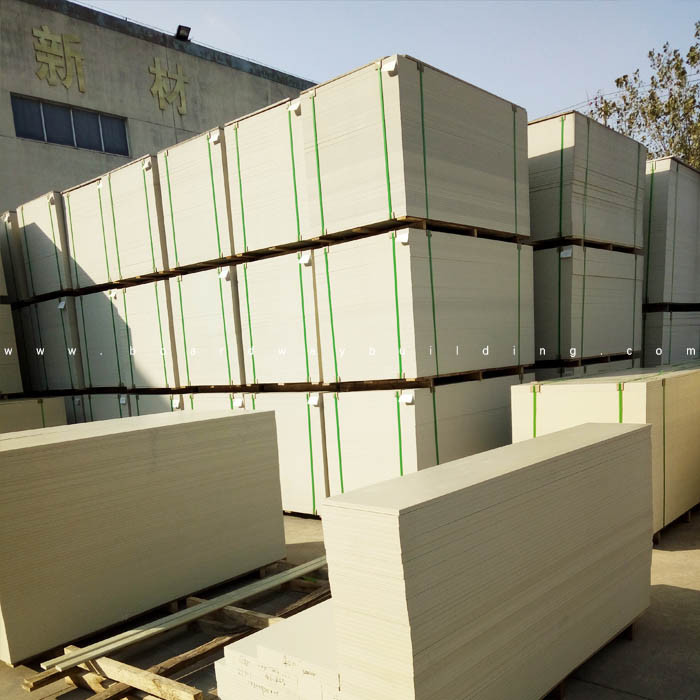

PVC formwork, also known as PVC concrete formwork, a valuable construction material, has gained increasing popularity in the building industry due to its versatility and efficiency. As a leading manufacturer and supplier of construction materials, Boardway is dedicated to providing insights into the world of PVC formwork. In this article, we will explore the advantages and disadvantages of PVC formwork to help you make informed decisions for your construction projects. By the end of this article, you will have a comprehensive understanding of PVC formwork and whether it's the right fit for your specific needs.

PVC formwork for slabs

PVC formwork for beams

PVC formwork for walls

Understanding PVC Formwork

PVC formwork, also known as PVC concrete formwork, is a construction tool used to shape concrete structures during the pouring and curing process. It is made of Polyvinyl Chloride (PVC) material and designed to be lightweight, durable, and reusable. Its popularity stems from its role in simplifying the construction process, reducing labor and material costs, and enhancing project efficiency.

The Pros of PVC Formwork

PVC formwork offers several key advantages:

- Durability: PVC formwork is known for its durability and the ability to withstand multiple uses, reducing the need for constant replacements. This leads to cost savings and less environmental impact.

- Lightweight: PVC formwork's lightweight nature makes it easy to handle and transport to the construction site. This can lead to increased worker efficiency and reduced labor costs.

- Cost-Effective: PVC formwork can significantly lower construction costs due to its reusability and long lifespan. This results in substantial savings over time.

- Reduced Labor: The ease of installing and removing PVC formwork reduces the labor required for construction projects, making it a practical choice for many builders.

- Environmental Benefits: PVC formwork's reusability and reduced need for replacements can contribute to lower environmental impact and reduced waste compared to traditional formwork materials.

The Cons of PVC Formwork

Despite its advantages, PVC formwork also has certain drawbacks:

- Environmental Concerns: PVC is made from plastic and contains chlorine, which can be harmful when incinerated. Proper disposal and recycling are essential to mitigate environmental concerns.

- Limited Load Capacity: PVC formwork may not be suitable for projects with heavy load-bearing requirements, as it has a limited load capacity compared to traditional materials like steel or wood.

- Initial Investment: While PVC formwork can lead to long-term cost savings, there may be a higher initial investment compared to traditional formwork materials.

- Maintenance: Regular maintenance is necessary to ensure the long-term performance of PVC formwork, including cleaning and repairs when needed.

- Temperature Sensitivity: PVC formwork can be sensitive to temperature fluctuations, which should be considered during installation and use in regions with extreme climate conditions.

Applications and Case Studies

Several construction projects have successfully used PVC formwork to their advantage. These real-world examples demonstrate how PVC formwork's benefits were leveraged for cost savings and efficiency.

1. High-Rise Residential Building

In a project involving the construction of a high-rise residential building, PVC formwork was utilized for casting concrete walls and columns. The lightweight nature of PVC formwork allowed for easier transportation and installation, resulting in significant labor savings. Its durability ensured that the formwork could be reused multiple times, further reducing material costs. This case exemplifies how PVC formwork can lead to substantial cost savings in large-scale residential construction.

2. Commercial Shopping Complex

A commercial shopping complex required a speedy construction process to meet tight deadlines. PVC formwork was chosen for its quick assembly and disassembly, resulting in a faster turnover of formwork elements between different sections of the project. This efficiency reduced construction time and associated labor costs, demonstrating the advantage of PVC formwork in commercial projects with tight schedules.

3. Bridge Construction

In a bridge construction project, where versatility and durability are crucial, PVC formwork was used for forming the bridge's abutments. Its ability to withstand exposure to the elements and resist corrosion made it a practical choice. The reusability of the formwork elements across multiple bridge sections contributed to long-term cost savings in materials and labor, making it an ideal solution for infrastructure projects.

4. Sports Center Construction

In the construction of a modern sports center, the design called for large, exposed concrete surfaces with a smooth and pristine finish. PVC formwork was chosen for the concrete casting of walls and columns, especially in areas where no brick cladding or plastering was required. PVC formwork's smooth and high-quality surface finish eliminated the need for additional treatments such as plastering, rendering, or painting. This not only saved time but also reduced the overall construction cost significantly. The ability to achieve an exceptionally smooth concrete surface directly from the formwork contributed to the aesthetics of the sports center and underscored the cost-efficiency of using PVC formwork in projects with a focus on architectural detailing.

In summary, PVC formwork offers significant advantages in terms of durability, cost-effectiveness, and reduced labor. However, it's crucial to be mindful of environmental concerns, load-bearing limitations, the initial investment, and the need for regular maintenance. Careful consideration of these factors is essential when choosing PVC formwork for your specific construction project. As a leading Chinese manufacturer and supplier of construction materials, Boardway is committed to providing high-quality PVC formwork solutions and customized services tailored to your needs. Whether you're planning residential, commercial, or industrial construction, PVC formwork offers a world of possibilities, and we're here to assist you in making the right choice.

- Experience the Best in PVC formwork with Boardway

- CONTACT NOW